The ability to use different filaments is crucial to Fused Deposition Modelling (FDM) 3D printing, as these thermoplastic materials dictate the final quality, mechanical properties (such as strength and flexibility), and potential applications of the printed object. Filaments are supplied in spools with standard diameters (commonly 1.75mm and 2.85mm). The selection process requires meticulous evaluation of factors, including material properties (e.g., strength, heat resistance), printing temperature, and bed adhesion. The world of filaments has expanded beyond basic PLA and ABS to include specialized engineering-grade options like Nylon and Polycarbonate, allowing users to create everything from simple prototypes to functional, multi-material end-use parts.

Your First Steps with Any 3D Printer

The successful utilization of an

FDM 3D printer, particularly when transitioning between diverse materials, necessitates rigorous adherence to fundamental setup and operational protocols.

Unboxing, Assembly, and Safety Checks

The essential material in FDM printing is the filament, a thermoplastic material supplied in long, thin strands wound onto spools. Prior to initiating any print, the printer must be correctly assembled, and safety checks must be conducted. When using certain materials, such as ABS or HIPS, it is crucial to ensure proper ventilation or the use of heated enclosures due to the emission of potentially harmful fumes during the printing process.

The Importance of a Perfectly Levelled Print Bed

Print bed preparation is a critical factor influencing overall print quality and part adherence. Certain materials, notably ABS, Nylon, and Polycarbonate (PC), are prone to warping, which mandates the use of a heated bed and sometimes specific bed preparations for successful printing. Proper bed levelling establishes the foundation for achieving optimal first-layer adhesion, which is paramount for overall part strength and preventing print failure.

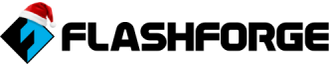

How to Load and Unload Filament: A Universal Skill

Filaments are typically available in two standard diameters: 1.75mm and 2.85mm. The material is loaded from the spool and fed into the printer's extruder. When switching between material types, particularly those with highly divergent printing temperatures (e.g., PLA to Nylon), careful unloading is required to prevent residual contamination or clogging. For hygroscopic materials such as Nylon, PC, and Flexible filaments (TPU/TPE), ensuring the material is dry and stored correctly before loading is a critical preparation step.

Running Your First Calibration Print (e.g., a Benchy or Calibration Cube)

Initial calibration prints are essential for fine-tuning the machine’s performance. Test prints allow the operator to assess material suitability and fine-tune critical parameters such as print speed, temperature, and layer height to optimize quality and functionality.

How to Use a 3D Printer for Different Filaments

The mechanical properties and successful processing of 3D prints are directly dependent upon the selection of the appropriate thermoplastic material.

How to Print with PLA (Polylactic Acid)

PLA filament is often recommended as the optimal starting point for novice users due to its inherent ease of use.

-

Ideal Printer Settings: PLA requires a low printing temperature, typically ranging from 180–230°C for the nozzle and around 50°C for the print bed. Minimal warping occurs with this material.

-

Properties and Limitations: PLA exhibits excellent detail reproduction and layer adhesion. It is derived from renewable resources and is biodegradable under specific industrial composting conditions. However, its functional use is limited by low heat resistance (approximately 60°C) and a tendency to be brittle. PLA is primarily suitable for low-cost, low-function parts.

How to Print with PETG (Polyethylene Terephthalate Glycol)

-

Ideal Printer Settings: PETG prints at higher temperatures, generally 220–250°C at the nozzle and 75–90°C for the heated bed. It exhibits less warping than ABS.

-

Challenges: This material is prone to stringing, which necessitates meticulous fine-tuning of retraction settings within the slicer software.

-

Key Advantages: PETG offers excellent durability, water resistance, good chemical resistance, and is UV-resistant, making it preferable for outdoor applications over ABS or PLA.

How to Print with ABS (Acrylonitrile Butadiene Styrene)

-

High Temperature Requirements: ABS requires high printing temperatures (220–250°C nozzle) and a significantly heated bed (95–110°C).

-

Managing Warping: ABS tends to warp during printing, which often necessitates the use of a heated enclosure and careful temperature control to achieve accurate dimensions.

-

Safety and Post-Processing: ABS emits potentially harmful fumes during extrusion, making good ventilation essential. A key advantage is its ability to be smoothed using acetone vapour for a glossy finish.

How to Print with TPU (Thermoplastic Polyurethane)

TPU, a component of the flexible Thermoplastic Elastomer (TPE) family, is utilized for parts requiring elasticity and high impact resistance.

-

Printing Challenges: Due to its flexible nature, TPU printing is generally better suited for direct drive extruders and requires significantly slower print speeds.

-

Material Handling: TPU is hygroscopic, meaning it absorbs moisture from the air, and must be dried before use and kept dry during extended print jobs.

-

Applications: TPU is highly suitable for creating impact-resistant parts, wearable items, seals, and gaskets.

Mastering Your Slicer Software

Slicer software (e.g., UltiMaker Cura) translates the 3D model into printable layers and determines the critical parameters that dictate print success.

Understanding the Most Critical Slicer Settings (Temperature, Speed, Retraction)

Successful printing hinges on managing these three core settings:

-

Temperature: Each filament type has an optimal temperature range for both the nozzle and the bed; incorrect temperatures lead to poor print quality and compromised layer adhesion. Moving to higher-performance materials correlates with an increase in required printing and bed temperatures.

-

Speed: Print speed must be adjusted according to the material; flexible filaments like TPU require substantially slower print speeds.

-

Retraction: Fine-tuning retraction distance and speed is vital, particularly for materials like PETG, which are notably prone to stringing.

Creating and Saving Custom Profiles for Each Filament Type

Given the vast differences in temperature, speed, and handling requirements across filaments, professional practice dictates creating and saving custom profiles within the slicer software. If multiple materials are loaded, especially those with different bed temperature requirements, it may be necessary to define a new material profile with equal bed temperatures that are compatible with all simultaneously used filaments.

The Role of Supports and Adhesion (Brims, Rafts, and Skirts)

Supports and adhesion tools are crucial for achieving complex geometries and ensuring print stability:

-

Support Materials: Support materials are essential for printing complex geometries with overhangs. These can be breakaway or dissolvable.

-

PVA (Polyvinyl Alcohol): A widely compatible support material that is water-soluble and often used with PLA.

-

HIPS (High Impact Polystyrene): Used as a support material for ABS, as it is soluble in D-limonene.

-

PLA: Due to its poor adhesion to most other materials (PETG, ABS, ASA), PLA can function as an easily peelable support material with zero clearance.

-

Adhesion Techniques: Certain materials necessitate specific bed preparation. Using a sticky coating like glue stick on the textured bed can facilitate release for flexible materials while ensuring adhesion for others, especially when mixing filaments. Adhesion mechanisms like brims or skirts can help mitigate warping in materials such as ABS or Nylon.

Troubleshooting 101: Common Problems and How to Fix Them

Successful additive manufacturing often requires iterative troubleshooting based on material-specific behaviours.

Problem: The First Layer Won't Stick to the Print Bed

Failure of the initial layer to adhere is a fundamental flaw that compromises the entire print.

-

Solution: Ensure the print bed is perfectly level and heated to the optimal temperature for the selected filament (e.g., 50°C for PLA, 95–110°C for ABS). Use a heated build volume or enclosure to mitigate warping in high-temperature materials like ABS and Nylon. Applying glue stick is a versatile solution that aids adhesion across various filament types.

Problem: Clogged Nozzles and How to Clear Them

Nozzle clogging interrupts the material flow and often requires intervention.

-

Prevention: The use of specialized filaments such as carbon fibre-filled or metal-filled filaments—which are abrasive—may necessitate the use of hardened nozzles to prevent premature wear.

-

Mitigation: Ensure correct filament drying, as the hygroscopic nature of materials like Nylon and PC can cause moisture to flash into steam inside the nozzle, leading to defects or blockages.

Problem: Stringing or "Hairs" Between Parts of Your Print

Stringing is the unintentional creation of thin plastic strands across open spaces.

-

Solution: This is frequently encountered when printing PETG. The primary solution is the fine-tuning of retraction settings (distance and speed) in the slicer software. Furthermore, printing flexible materials like TPU/TPE requires slower speeds, which may also reduce stringing issues.

Problem: Prints Failing Mid-Way Through

Mid-print failures are often attributed to environmental factors, material properties, or compromised structural integrity.

-

Warping/Delamination: Maintain appropriate temperature control (nozzle and bed) to ensure optimal layer adhesion, reducing the risk of delamination, especially with high-temperature materials.

-

Moisture: Failure in hygroscopic materials (Nylon, TPU, PC) may be linked to moisture absorption, leading to weakened parts and inconsistent extrusion.

-

Support Failure: For complex prints, ensure support structures are adequately rigid; lightweight supports should use interface layers with sufficient thickness (e.g., 7 solid interface layers) to provide a stable surface.

You Now Know How to Use a 3D Printer

The versatility of FDM 3D printing is fundamentally driven by the diverse landscape of available filaments. By understanding the mechanical properties and specific printing requirements—from the low heat resistance of PLA to the exceptional strength of PC—makers can strategically select materials to meet complex project demands.

The industry is currently witnessing a rapid evolution in materials science, with emerging trends pointing towards advanced composite materials (nano-reinforced, bio-based), expanded functional properties (electrical/thermal conductivity, antimicrobial, self-healing), and crucial sustainability innovations (fully biodegradable filaments, improved recycling). As 3D printing continues its advance, staying informed about these material developments and mastering advanced printing techniques is essential for harnessing the full potential of additive manufacturing.