The

global 3D printing market is expected to exceed 100 billion US dollars by 2025, with a compound annual growth rate of more than 18%. The significant growth is closely related to the deep integration of cutting-edge technologies such as artificial intelligence, new materials, and automation. In this article, we will analyze the cutting-edge trends in 3D printing innovation, including AI-driven generative design, bioprinted organs, and the global standardization of sustainable materials, providing some insights into the future landscape of 3D printing technology for in-depth 3D printing enthusiasts and investment experts in the 3D printer industry.

The New Wave of 3D Printer Innovation and 3D Printing Trends

The current 3D printing industry is at a critical inflection point on its technology maturity curve. Traditional additive manufacturing has many limitations, such as slow speed, limited materials, and even complex post-processing. Fortunately, through multiple technological breakthroughs, many innovative 3D printing technologies have been systematically addressed. These innovations not only enhance technical performance but more importantly, lower the application threshold, enabling small and medium-sized enterprises to also enjoy the dividends of additive manufacturing.

AI-Driven Design for A Top 3D Printing Trend

Artificial intelligence technology has now been integrated into our daily lifestyle and is also changing the design paradigm of 3D printing. Generative design technology automatically explores thousands of design schemes through algorithms and optimizes structural performance under engineering constraints. For instance, generative design software from companies like Autodesk has been able to shorten the design cycle from several weeks to just a few hours, while achieving a remarkable effect of reducing material usage by 40% and weight by 55%. Flashforge slicing software,

Orca Flashforge, has embedded AI that can help you turn ideas into reality. The AI 3D Model Generator converts any image or text description into a 3D model, unlocking unlimited creative possibilities.

In addition, machine learning plays a crucial role in process optimization. By analyzing historical printing data and real-time sensor information, the AI system can predict defects and automatically adjust printing parameters to achieve zero-defect production. Research from Purdue University shows that an active learning framework based on Bayesian optimization can significantly reduce the parameter optimization time for nanoscale 3D printing and lower the geometric accuracy error to within the measurement accuracy range. Convolutional neural networks (CNNS) are widely used in layer-by-layer defect detection, while reinforcement learning enables dynamic parameter adjustment.

High-Speed Production for An Innovative 3D Printing Shift

Speed has always been the main bottleneck restricting the large-scale application of 3D printing, but the emergence of Continuous Liquid Interface Production (CLIP) technology has completely changed this situation. The CLIP technology, pioneered by Carbon, enables layer-free continuous printing by precisely controlling the interaction between light and oxygen. It is 25 to 100 times faster than traditional UV curing technology, maintaining a thin layer of uncured resin between the oxygen-permeable window and the print, thus avoiding the time-consuming peeling step in traditional methods.

In the

FDM printing field, emerging manufacturers such as

Flashforge have launched high-speed printers with a printing speed of up to 600mm/s and an acceleration of 20000mm/s², with an additional purchase price of only $359. These breakthroughs have enabled 3D printing to shift from small-batch prototyping to medium-batch production.

Advanced & Multi-Material 3D Printer Innovation

Multi-material 3D printing is breaking through the performance limitations of a single material, achieving functional integration and material gradient design. In FDM technology, the multi-nozzle system and material switching mechanism enable a single print to use multiple materials and colors. Flashforge's

multi-filament AD5X 3D printer can achieve high-precision multi-material printing, suitable for complex components that require both rigidity and flexibility. It has also made significant breakthroughs in full-color printing. Through the CMYK ink system, these technologies can achieve voxel-level control of over 600,000 colors, creating realistic gradient and blending effects. Compared with the traditional RGB color mixing, the CMYK method offers more accurate color reproduction and less ink consumption. However, color-mixing 3D printing still faces challenges - experiments in FDM attempting to create any color by blending cyan, magenta, yellow and white filaments have shown that due to the non-laminar flow characteristics of the melt, the actual results are often unsatisfactory. This is also one of the key areas for future 3D printing industry researchers to break through.

Large-Format Printing for A Massive 3D Printing Trend

Large-format 3D printing is transforming the production methods in industries such as construction, aerospace, and shipbuilding. In the field of architecture, Apis Cor collaborated with the Dubai municipal government to build the world's largest 3D-printed structure at that time - a two-story office building 9.5 meters high. Chinese company Winsun has utilized 3D printing technology to mass-produce prefabricated house components, demonstrating the potential of this technology in addressing the global housing crisis. Companies like ICON are commercializing 3D-printed buildings, enabling rapid and economical residential construction through proprietary robotic systems, software and advanced materials. The aerospace field also benefits from large-format printing. Lockheed Martin has used Sciaky's electron beam additive manufacturing (EBAM) technology to manufacture titanium alloy satellite fuel tank domes that are up to 6 meters high and 1.2 meters wide, significantly reducing the production cycle. Boeing's 777x engine contains over 300 3D-printed components, which have reduced weight and costs through component integration. Stratasys' large-format FDM printers such as the F770, offer cost-effective large component production capabilities for the aerospace industry. The challenges of large-format printing include material consistency, thermal management and quality control, but with technological advancements, these issues are gradually being addressed.

Automatic Hot end Change System

The Automatic Hot End Change System is a key cutting-edge technology for achieving efficient multi-material or multi-color printing in the field of 3D printing. The automatic hot end replacement system mainly uses mechanical arms, magnetic attraction or snap-on methods to automatically replace different hot ends during the printing process. Each hot end can correspond to filaments of different materials or colors. As a leading brand in the 3D printing industry, Bambu Lab's VORTEK system supports wireless magnetic automatic replacement for up to 7 hot ends. Each time VORTEK is replaced, there is no need for material purge, which can achieve zero-waste color switching and significantly reduce material loss. The hot end is embedded with a chip, which synchronizes real-time temperature, material, heating status and other information to the main controller through a high-frequency wireless protocol, achieving precise temperature control and intelligent seasoning recognition. Overall, the automatic hot-end replacement system has become a significant breakthrough in multi-material/multi-colour efficient 3D printing, representing a new direction for the upgrade of desktop and industrial-grade 3D printing technologies. Its features of zero waste, high efficiency, and easy scalability are promoting the implementation of new application scenarios in 3D printing.

Hybrid & 5-Axis 3D Printer Innovation

With the continuous maturation of software and hardware, hybrid manufacturing is becoming the mainstream choice for the production of high-value components. Hybrid manufacturing integrates additive and subtractive manufacturing technologies within a single workspace, enabling integrated production from roughing to finishing. Five-axis and multi-axis printing technologies break through the limitations of traditional planar stacking. By changing the build direction and printhead orientation, multi-axis systems can create deposition paths along curved surfaces, reducing step effects, improving surface quality, and achieving more uniform material distribution. Siemens' NX AM Multi-Axis software is specifically designed for such complex path planning, supporting complete five-axis AM path planning for both robots and machine tools. Six-DOF robotic arm printing systems demonstrate the ability to perform conformal printing on complex curved surfaces; although the mechanical accuracy is lower than at the CNC stage, accuracy can be enhanced through path correction using vision-guided tools. Applications of hybrid manufacturing include prototyping, small-batch production, component repair, and coating. Companies such as Phillips combine Haas CNC machining centers with Fronius' arc welding, Laserline's metal powder, and Meltio's wire DED technology to provide end-to-end hybrid manufacturing solutions. This integration allows manufacturers to 3D print parts to near-net-shape and then perform finishing in the same setup, applying different additive materials to optimize design, weight, and strength.

Bioprinting for An Innovative 3D Printing Frontier

Bioprinting represents the most revolutionary application of 3D printing technology - creating living tissues and organs. At present, there are over 100,000 people on the organ transplant waiting list worldwide, and many of them may die while waiting. The 3D bioprinting market is expected to reach 1.37 billion US dollars by 2032, with a compound annual growth rate of 12.7%. Bioprinting, by printing personalized organs using the patient's own cells, is expected to fundamentally solve the problem of organ shortage and reduce the risk of rejection.

This technology involves three key stages. During the pre-printing stage, 3D digital models are created using MRI or CT scans, and bio-inks containing cells, biomaterials and growth factors are prepared. During the printing stage, bio-ink is deposited layer by layer using extrusion, inkjet or laser-assisted bioprinting technology. The post-printing stage promotes tissue maturation and mechanical strengthening through cultivation.

Researchers at Stanford University have developed new tools to design and 3D print complex vascular trees required for organs. Their algorithm generates vascular networks about 200 times faster than previous methods. A team from MIT has demonstrated a new 3D bioprinting technology that integrates process control methods to limit defects, enhancing the repeatability and resource efficiency of printed tissues. Scientists from Northeastern University have applied for a patent for a new type of elastic hydrogel material specifically designed for 3D printing of soft living tissues, which may soon enable the printing of blood vessels and human organs.

Automation & Post-Processing for A Core 3D Printing Trend

Post-processing has long been a bottleneck in the 3D printing workflow, consuming a significant amount of time and human resources. Automation solutions are changing this situation. Artificial intelligence is playing an increasingly important role in quality control. Machine learning technology is applied to defect prediction, process parameter optimization and real-time production quality monitoring. Computer vision systems can identify the geometry of components and automatically select appropriate finishing parameters. Adaptive surface treatment technology can adjust the sandblasting intensity or polishing profile in real time based on sensor feedback.

The application of robot technology in the post-processing of metal AM is also on the rise. In the near 2026, key trends in post-processing include: automation is no longer an option but a necessity, sustainability becomes a growth focus, and enhanced security measures are of vital importance.

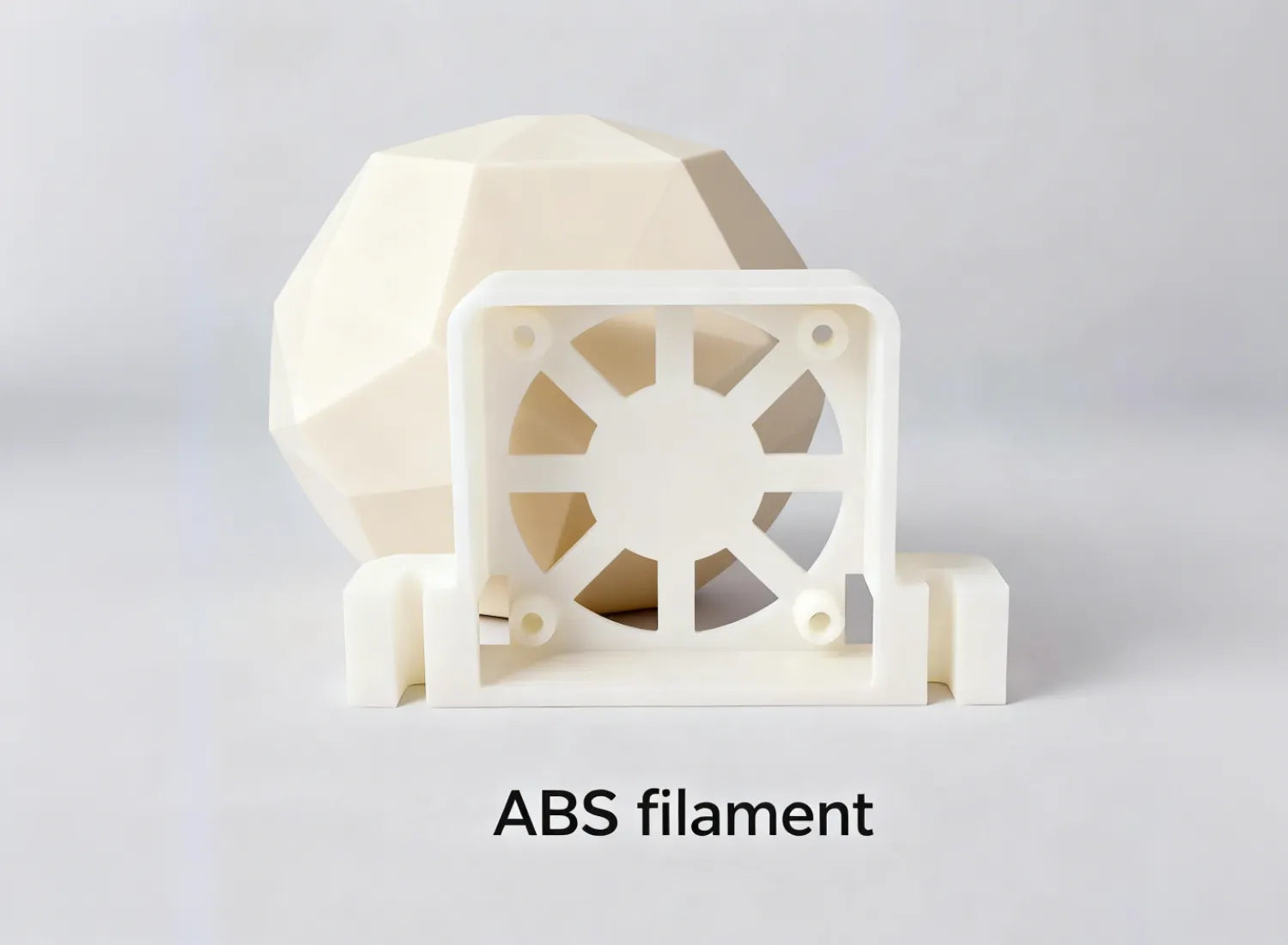

Sustainability for An Eco-Friendly 3D Printer Innovation

Compared with traditional subtractive manufacturing, additive manufacturing is essentially more efficient, using only the exact amount of materials required. In selective laser sintering (SLS), unused powder is cleaned and reused in subsequent batches, with a material recovery rate of up to 80%.

Bio-based materials offer renewable alternatives.

PLA 3D printing filament is a filament extracted from corn or sugarcane, which is easy to print and biodegradable under industrial conditions. Some resin manufacturers have begun to offer plant-based or soy-based resins to support sustainability goals in high-detail printing. Composite materials filled with wood, hemp and algae reduce the overall polymer content and add a touch. Although they are not necessarily biodegradable, they reduce the reliance on petrochemical products. The contribution of 3D printing to sustainability is not limited to materials. Production on demand reduces inventory requirements and waste caused by outdated products. Localized manufacturing reduces transportation distance and carbon emissions. The waste caused by product recalls and design changes was reduced through prototype optimization. Research shows that among various materials and part geometries, the environmental impact of AM is lower than that of traditional manufacturing processes, especially in cases of low output and complex parts.

Standardization for The 3D Printing Trend for Mass Adoption

Standardization is crucial for the transformation of 3D printing from a prototyping tool to a mass production technology. The additive manufacturing standard development structure jointly developed by ISO and ASTM International provides a framework for creating global technical standards. This structure develops standards at three levels: general standards (concepts, general requirements, guidelines, safety), broad standards for material or process categories (such as metal powders, powder bed melting), and specialized standards for specific materials or applications (such as aerospace, medical, automotive).

The adoption of the 3MF file format as an ISO standard (ISO/IEC 25422:2025) marks a significant advancement in the standardization of data exchange. Compared with the outdated STL format,3MF offers richer information encoding capabilities, eliminates repetitive efforts, reduces adoption barriers, and paves the way for scalable growth across the entire industry.

A quality certification system is being established. The AMQ certification program of ASTM Additive Manufacturing Center of Excellence (AM CoE) is based on international standards such as ISO/ASTM 52901:2017 and ISO/ASTM 52904:2019, providing a modular and comprehensive certification approach for additive manufacturing facilities. The DNV-ST-B203 standard of DNV is the first standard to provide an internationally recognized framework for high-quality metal additive manufacturing components in the oil and gas, maritime and related industries.

Standardization is also being advanced in the field of architecture. ISO/ASTM 52939:2023 stipulates the quality assurance requirements for construction projects using additive manufacturing technology, which are independent of the materials and process categories used. NASA and other institutions have issued minimum requirements standards for additive manufacturing components for manned spaceflight applications.

The feasibility of large-scale application is being verified. Although 3D printing still faces challenges in terms of speed, repeatability and quality control, high-speed printing technology, automation and AI integration, and hybrid manufacturing methods are driving industrial-scale applications. Companies like Slant 3D operate large printing farms with thousands of FDM printers, proving that 3D printing is more cost-effective than injection moulding for orders of less than 100,000 pieces. The aerospace, automotive, medical and consumer goods industries are leading the application of scalable 3D printing.

Conclusion for The Future of 3D Printing Trends and Innovative 3D Printing

3D printing technology is standing at the critical point of large-scale industrial application. The ten innovative advancements in 3D printing technology discussed in this article collectively form a complete picture of the transformation of additive manufacturing from prototype tools to mainstream production technologies. The pace of technological progress is encouraging, and many goals that once seemed out of reach are now becoming a reality. It is expected that in the next 3 to 5 years, we will witness breakthroughs in 3D printing in more fields.