Shipping Location

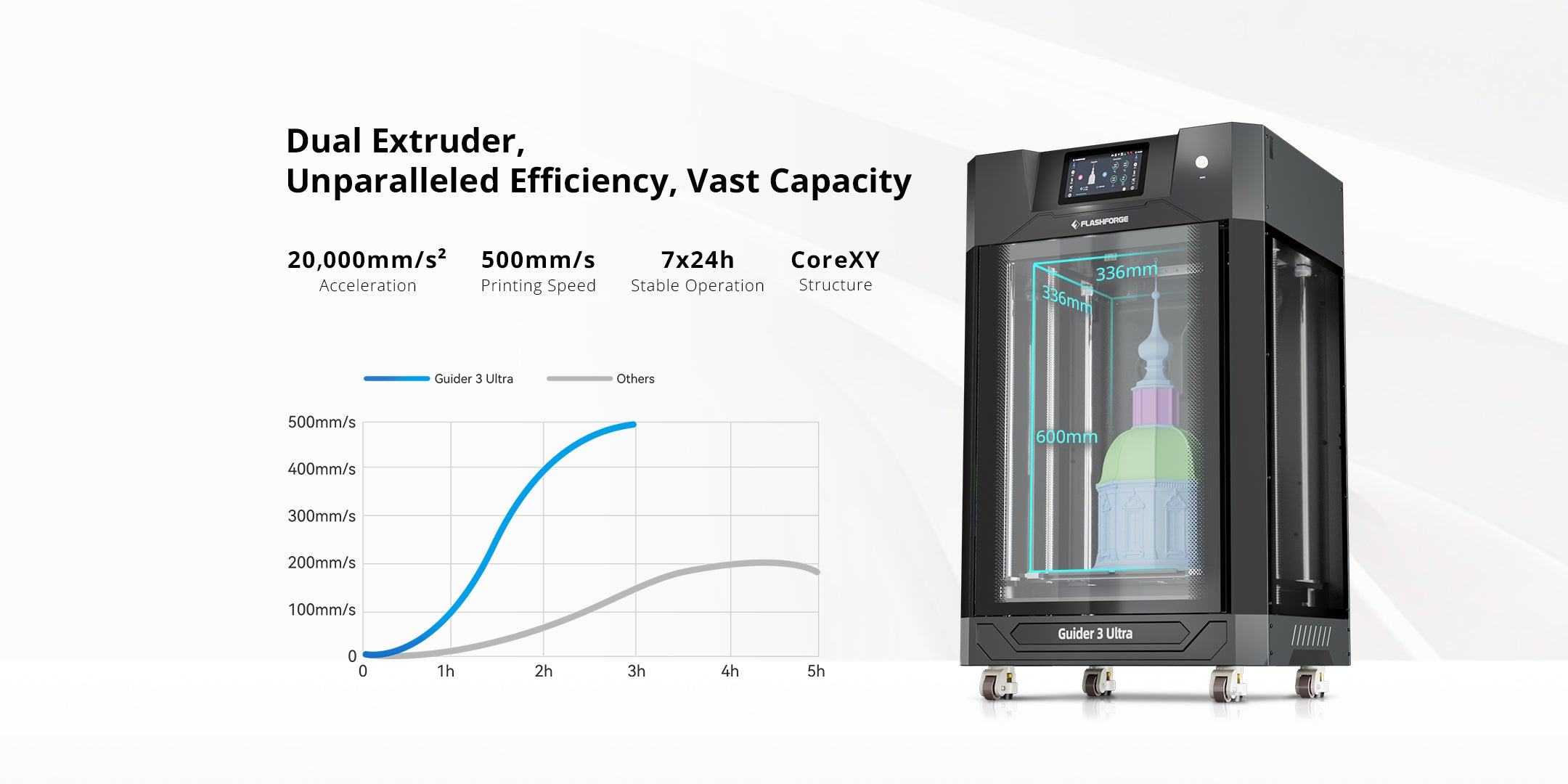

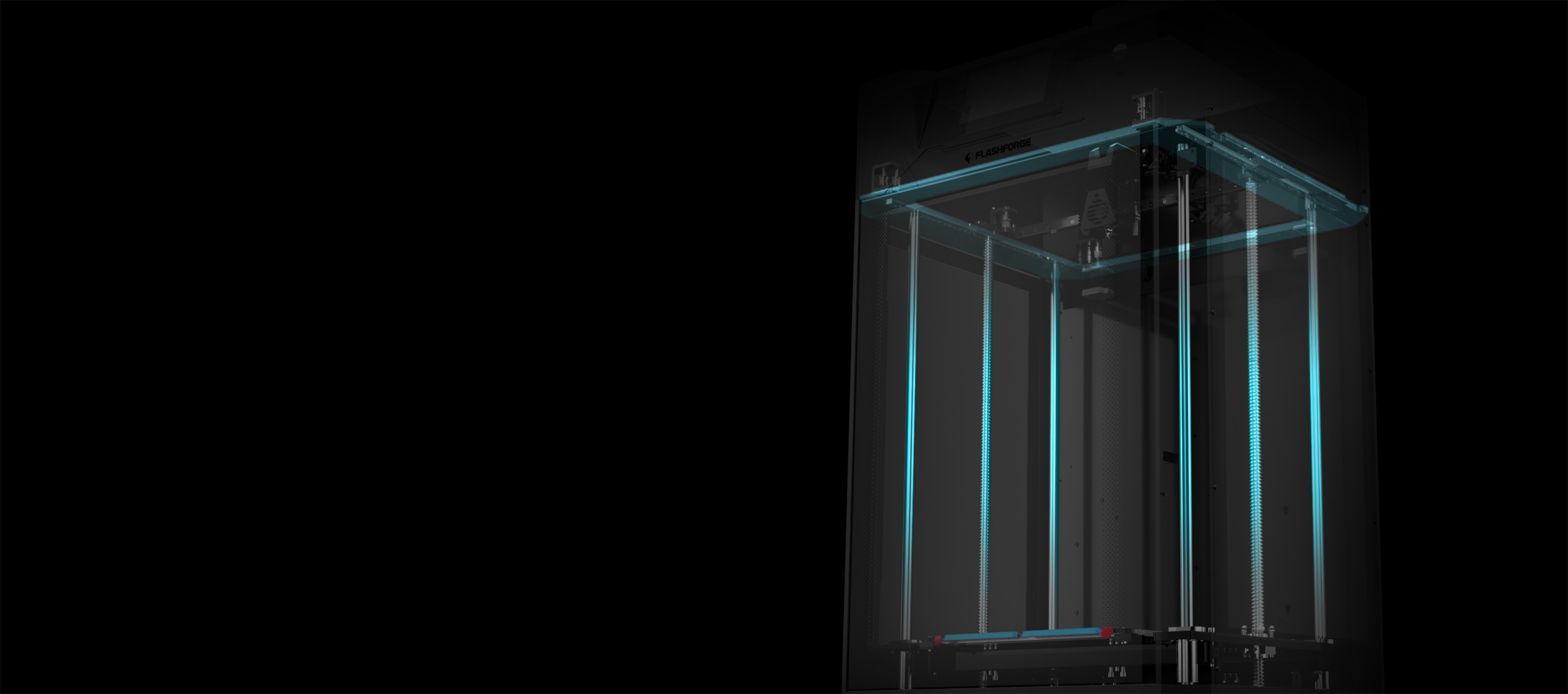

Core-XY Structure

Enhances Printing Precision

The Core-XY structure, with its metal components, provides high rigidity to reduce errors from vibrations or mechanical shifts. Its independently controlled X and Y axes also minimize the looseness and inaccuracies common in traditional belt-driven systems, ensuring greater precision and stability in printing.

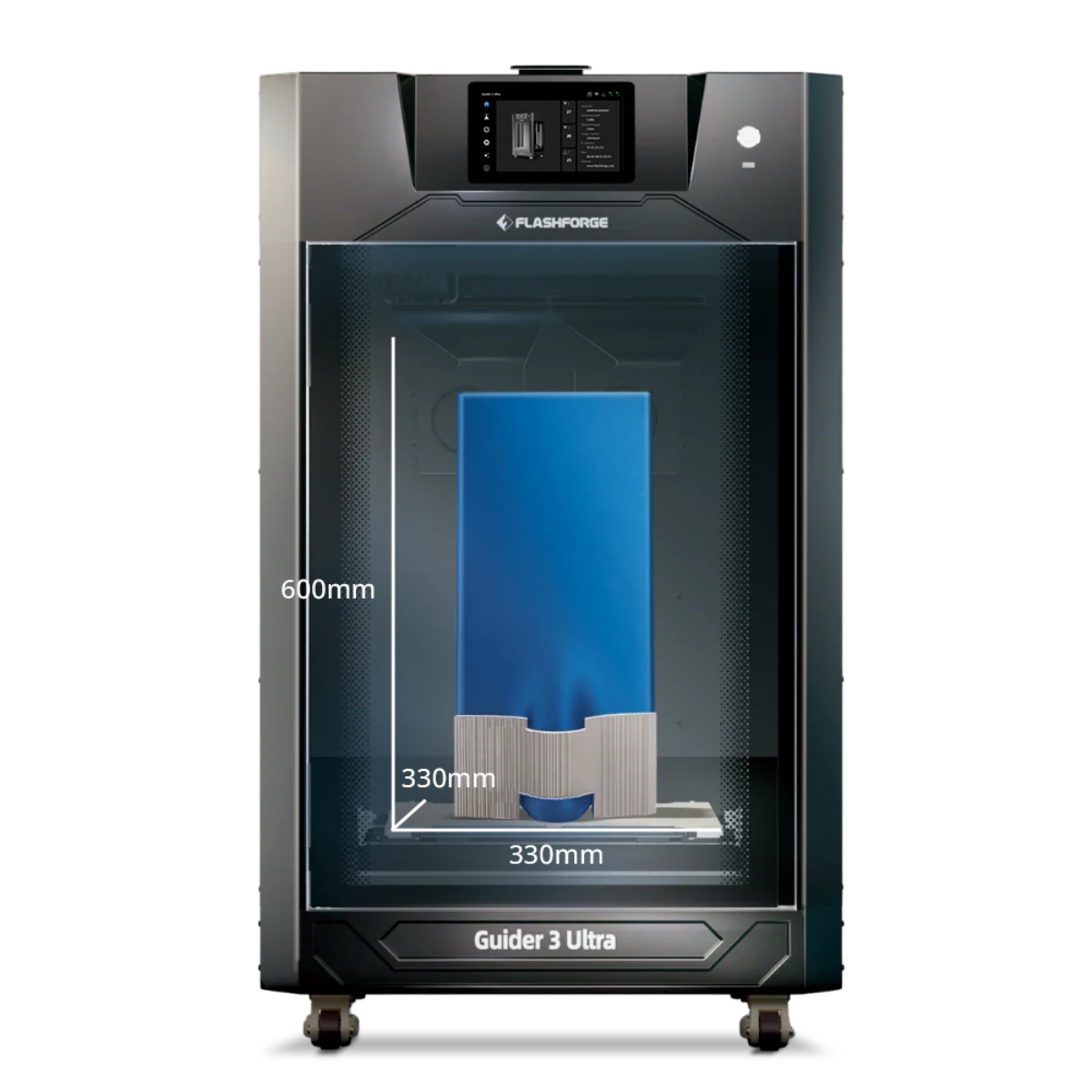

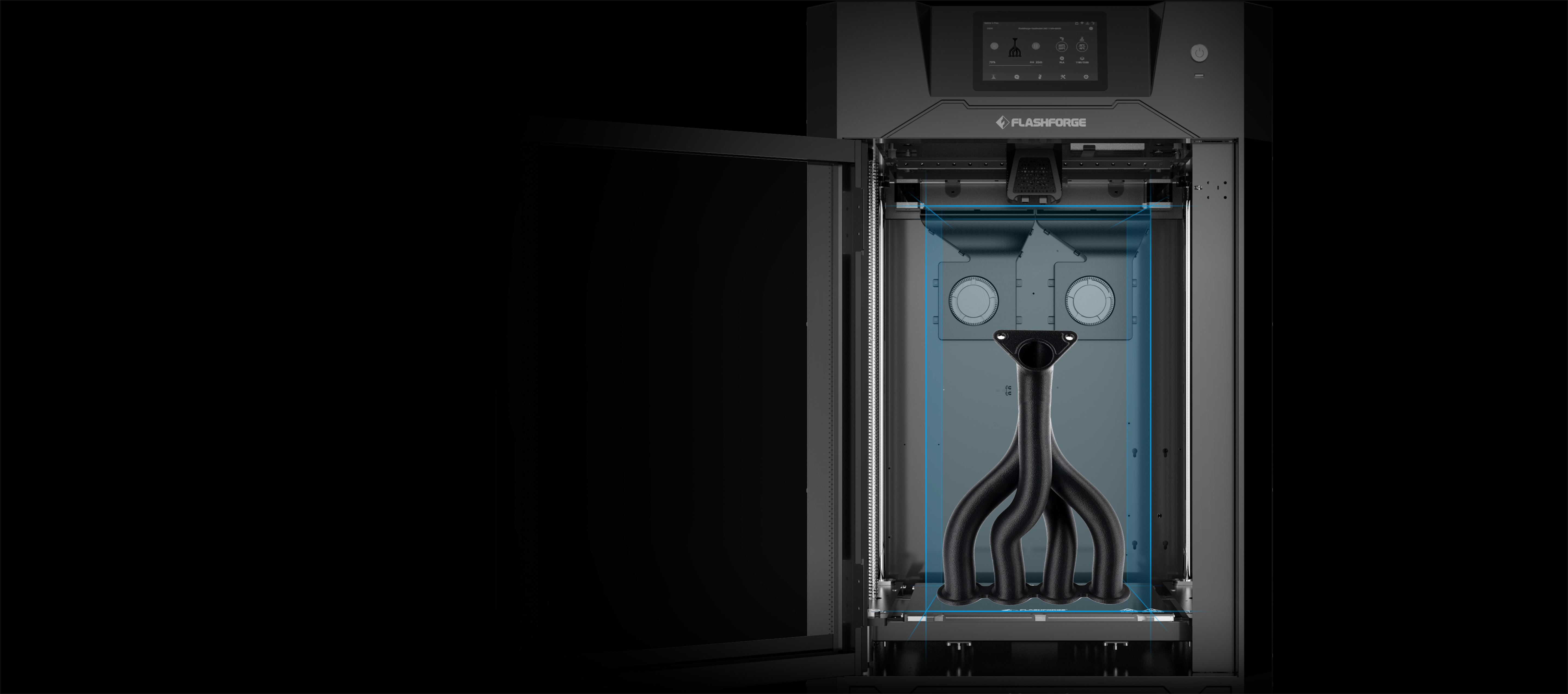

Large Size,

Expanding Printing

Boundaries

Accommodates a variety of model sizes with a maximum print height of 600mm, meeting all your large-scale printing needs.

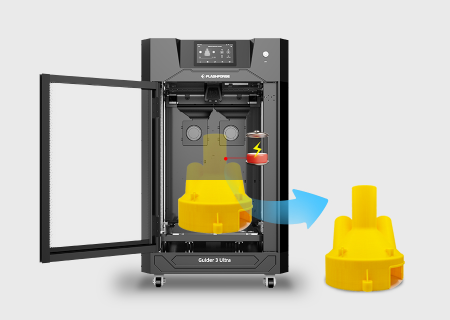

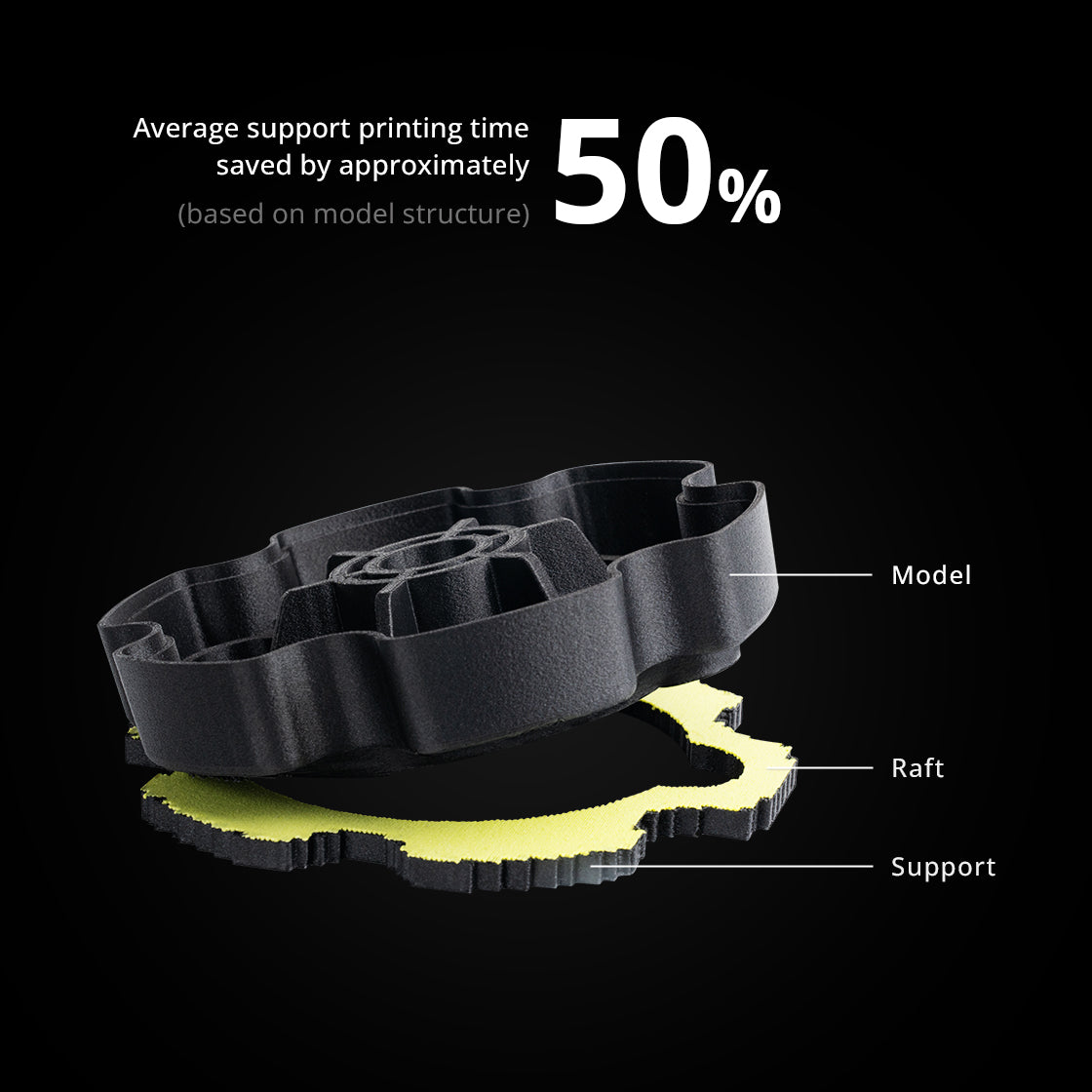

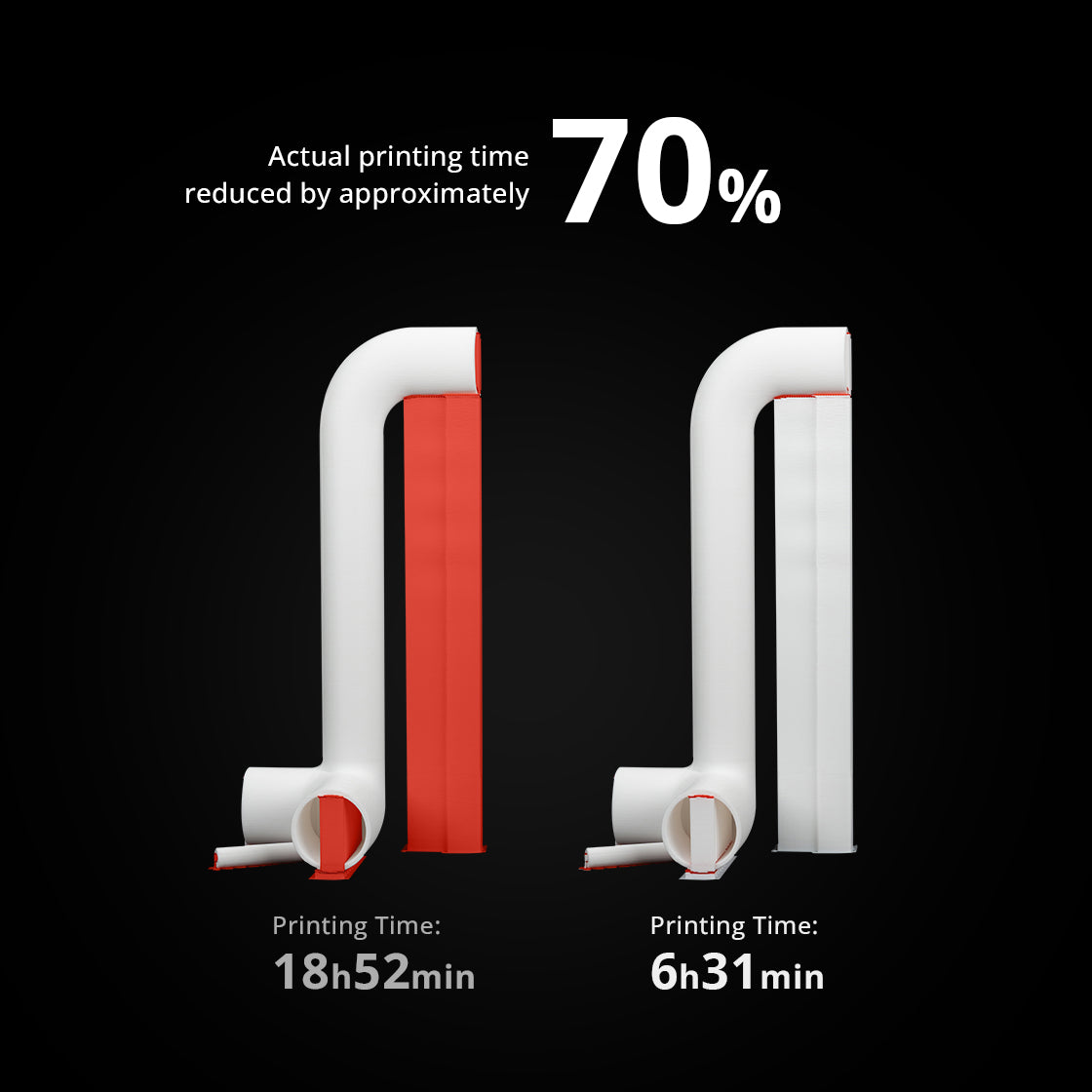

Raft Support

Combining advantages of self-supporting and breakaway supports, it saves support printing time and enables effortless support removal.

Why is time saved?

The support is printed with the same material as the model, minimizing extruder switches and reducing waiting time.

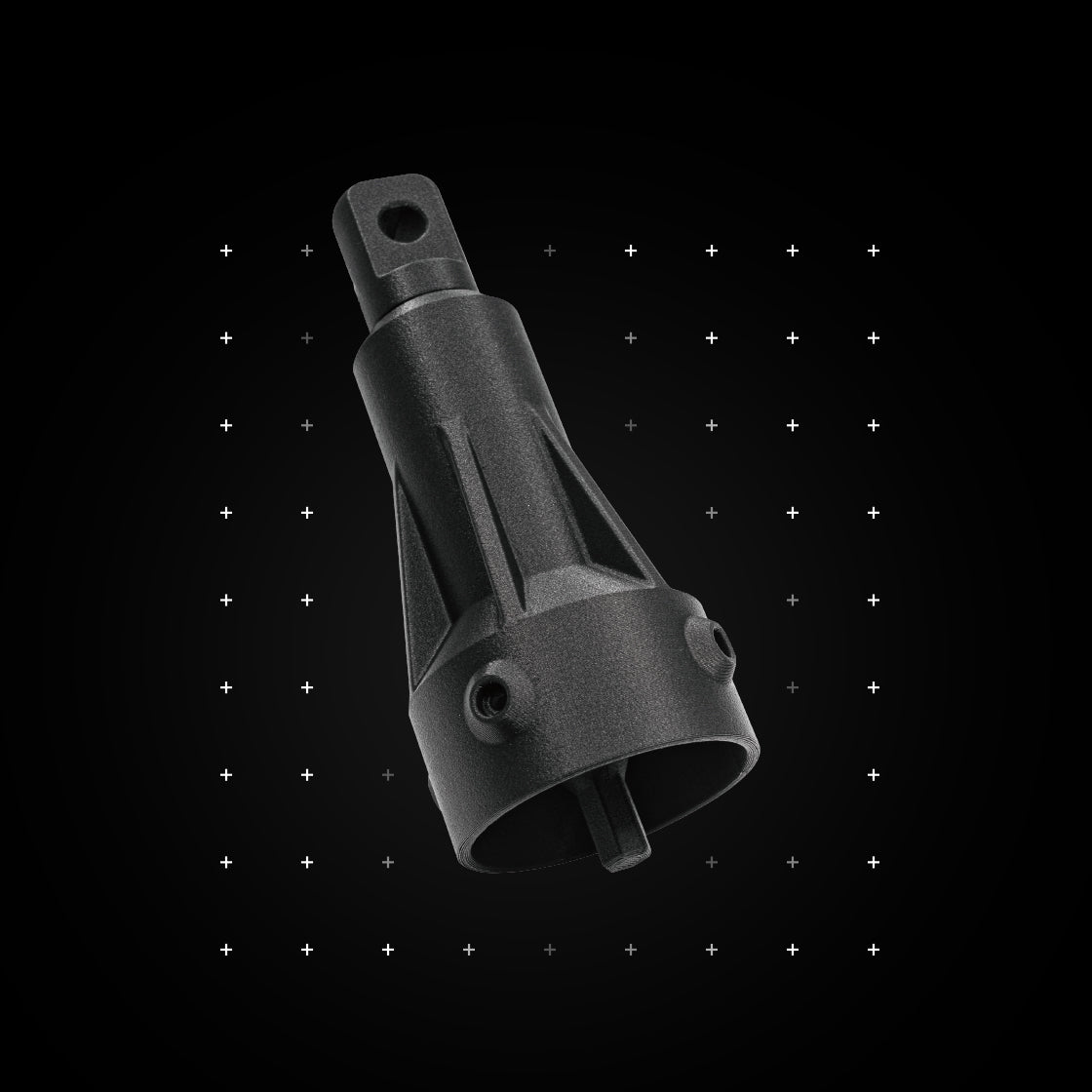

High Surface Quality

Dual Z-axis ball screws ensure precision, while vibration suppression and controlled extrusion improve surface quality and detail.

What's More

FAQ

Flashforge has product warehouses in many countries. Your ordered products will be shipped from your nearest warehouse. For products not stored in your regional warehouses, we'll send from Flashforge headquarter, China.

It depends on where you are. Orders processed here will take 5-7 business days to arrive. Overseas deliveries can take anywhere from 7-16 days. Delivery details will be provided in your confirmation email.

Flashforge FFF technology 3D printer provides you with a 12-month limited warranty for the host and a 3-month warranty for FFF technology 3D printer nozzle component. For more details, please click here.

*PLA/*PETG(0.4mm nozzle)

*TPU /PLA-CF/PETG-CF (0.6mm nozzle)

Note: Materials marked with * are recommended for printing.

The performance in printing of both products is comparable, as they are high-speed 3D printers, and they are both very user-friendly in operation. AD5M has a highly competitive product, while 5MP adds features such as a closed structure, built-in camera, and air filter cotton on the basis of 5M. If you have any questions during the purchasing process, you can contact the Flashforge support team.