When we were little, we would often want a toy and beg our parents to buy it for us. Now, when we want a toy, we just create it, model it, and then print it. 3D printing has revolutionized the way toys are designed and manufactured. 3D printing offers unprecedented opportunities for creativity and personalization. This additive manufacturing process creates complex and customizable objects layer by layer, unlike traditional methods like cutting, moulding, or casting. In this article, Flashforge will help toy enthusiasts explore 10 fun 3D printed toys that can be created through the magic of 3D printing.

Why Create 3D Printed Toys? The Power of Personalization and Innovation

The appeal of 3D printed toys stems from their remarkable flexibility, creativity, and potential for personalization. Unlike mass-produced items, 3D printing empowers individuals to take full control of the final product.

Unrivalled Customization for Your Perfect 3D Printer Toy

One of the most exciting aspects of 3D printing is its ability to customize every detail of a toy. Users can design models from scratch or modify existing ones by altering sizes, colours, or textures. This allows for the addition of personalized touches, such as a child's name or unique colour combinations, making each toy truly one-of-a-kind. With FDM printing, the choice of filament can further enhance customization, from glossy Silk PLA to realistic Matte PLA.

Innovation and Design Freedom: Creating Cool Toys to 3D Print

3D printing provides innovation and design freedom that allows for the creation of unique and complex toys previously unachievable with traditional manufacturing methods such as injection moulding or CNC engraving. This technology facilitates designs with moving parts, intricate details, and modular elements that can be assembled. For example, 3D printed action figures can feature multiple articulated joints, and educational toys can be designed for assembly, teaching engineering principles.

Cost-Effectiveness and Accessibility

While there is an initial investment in purchasing a 3D printer, creating toys through FDM 3D printing can become a cost-effective hobby or business over time. Instead of buying retail toys, you can print as many as needed using only filament and time. Furthermore, many digital design files for 3D printing are available for free online, which significantly reduces costs associated with design and prototyping. Services like JLC3DP also allow you to order models online if you do not own a printer.

Getting Started: Your Journey to Awesome 3D Printed Toys

Creating 3D printed toys is a straightforward process involving several key steps:

From Idea to G-Code: Sourcing and Preparing 3D Printer Files

The journey begins with a 3D digital model. You can either design your own using CAD software such as Tinkercad or Fusion 360, or download pre-designed models from popular platforms like Makerworld.com, Printables.com, Thangs.com, Thingiverse, or MyMiniFactory. Of course, you can also use

Orca-Flashforge's AI modelling function to convert pictures and text into models with one click, giving full play to your imagination. Once you have your 3D model, it needs to be converted into a printable format, typically an STL file. Slicing software, such as Cura or PrusaSlicer, is then used to prepare the G-code file, which dictates how the printer will build the object layer by layer.

Choosing the Right Filament for Your 3D Printed Toy Project

Filament is the material used by

FDM 3D printers to form the toy. The choice of material is crucial for the toy's properties, durability, and safety:

-

PLA (Polylactic Acid): This is a widely used and beginner-friendly filament due to its ease of printing and environmental friendliness. However, it can be brittle and is not waterproof, which means it may degrade with prolonged water exposure.

-

ABS: This filament offers greater durability and impact resistance, making it a better choice for toys that might endure rough play. It is also more water-resistant than PLA.

-

TPU: Known for its flexibility, TPU is ideal for toys requiring some stretch or bend.

-

PETG: White, black, red, and grey 3d printing filament were specifically mentioned for an Inertia Drifting Car Ornament, with this type of filament standing out as ideal consumables that highlight the material’s suitability for multi-colour FDM prints.

Printing and Polishing Your 3D Printer Toy

After loading the chosen filament and adjusting print settings—such as layer height, speed, and infill—the 3D printer commences the process of building the toy layer by layer. Printing at a lower speed is often recommended for higher quality results. Once printing is complete, post-processing steps may be necessary, including removing any support structures, sanding rough edges, or applying a paint finish for a polished appearance.

10 Inspiring Ideas for Your Next 3D Printed Toy Project

Here are ten inspiring ideas for FDM 3D printed toys, showcasing the versatility of technology:

Articulated Dragons

These are very popular FDM prints, featuring movable joints and detailed designs. They print in segments that connect without requiring assembly afterwards, resulting in a flexible toy that can bend and pose. The size, colour, and texture can all be customized. For anyone eager to turn the idea of a 3D printed dragon (like the beginner-friendly, poseable Flexi Fat Dragon that prints without supports) into reality, the

Step-by-Step Tutorial for DIY 3D Printed Dragons breaks down the process clearly, making it easy to replicate this popular FDM project.

Custom Chess Sets

FDM printing allows for the creation of unique chess sets, ranging from traditional to themed designs. The pieces can resemble characters from favourite movies, and the board itself can be customized, offering endless creative possibilities. An example is the 3D Chess (Star Trek TOS) set, designed to be printable without supports.

Fidget Toys

These engaging toys, like Fidget Spinners and Fidget Cubes, are easy to make and highly customizable in shape, weight distribution, and design. The Fidget Cubes MC Edition combines classic game elements with 3D printing, allowing users to choose and customize versions like dirt, grass, ore, or creepers by changing colours. The TIC TAC TOE (PRINT IN PLACE) game is another portable, support-free FDM print that can be completed in about 45 minutes.

Personalized Animal Figurines

FDM printing can create a variety of adorable animal figurines. The Moo Deng Baby Hippo is a super cute figurine with exquisite, lifelike details. For those who enjoy fan creations, the Toothless Face Keychain can be printed in separate coloured parts for its iconic look, working well with PLA. The Knitted Bear and Mama Bird & Baby Chick models, while having textures that benefit from high-detail printing, can also be achieved with FDM, providing options for kids' room decor or handmade-style gifts.

Educational Dinosaur Skeletons

These toys offer both fun and educational value. Each bone can be printed individually and then assembled, much like a paleontologist would. Sizes and complexities can vary, and wood-infused PLA filament can give a realistic texture.

Modular Robot Toys

FDM 3D printing provides a platform to experiment with robotics and mechanics. Many robot designs are modular, allowing for assembly of various parts. More advanced models can be enhanced with electronics and motors for movement and interaction.

Interactive Toy Vehicles

Classic favourites like toy cars, trucks, and planes can be designed with FDM. The Inertia Drifting Car Ornament is an example, printed with PETG filament, demonstrating dynamic effects in motion. Some designs come in parts for assembly, adding an extra challenge for children, and advanced models can incorporate working wheels or interchangeable parts.

Creative Toy Blocks

For younger children, FDM printed toy blocks can aid in developing motor skills and creativity. These can come in various shapes, sizes, and colours, from simple stacking blocks to intricate interlocking pieces, with textures or patterns adding to their play value. The GIANT Brick Christmas Tree is a large FDM project composed of nearly 600 PLA parts, demonstrating the scale possible with brick-style prints.

Functional Cat Toys

FDM 3D Printer with PLA filament can create toys that enrich pet play. The Cat Toy - Treat Dispenser Puzzle is an example, designed to let cats get snacks by turning a device. It features multiple printable parts without supports and can be fixed with super glue after printing. The Hide and Seek Cat Toy is another example, designed with many holes to keep cats entertained.

Unique Gadgets

FDM 3D printing is excellent for creating inventive gadgets. The Catapult Inspired By Leonardo da Vinci is an approximately 110mm tall model that has been iteratively updated for strength and to print without supports by removing material.

The Motorized Marble Run is another inspiring project for 10mm marbles, involving 3D printed parts alongside bearings, screws, motors, and other components for a fun circular motion. Other examples include a Giant Bubble Wand and the Keychain "Flip-it" Nano Pinball.

Choosing the Right 3D Printer for Your Toy Projects

When embarking on 3D printing toys, selecting the appropriate FDM printer is key. Flashforge offers a range of FDM printers suitable for various needs:

Beginner-Friendly 3D Printers for Kids and Adults

For those new to 3D printing, a user-friendly FDM machine is essential—particularly if you’re in the market for a 3d printer for toys. The Flashforge Adventurer 5M, which shines as a beginner-friendly 3D printer for both kids and adults, fits perfectly as a reliable 3d printer for toys while providing an accessible entry point into toy creation.

Advanced Features for Enhanced Creativity

As your skills or project complexity grow, more advanced FDM printers can offer enhanced features:

-

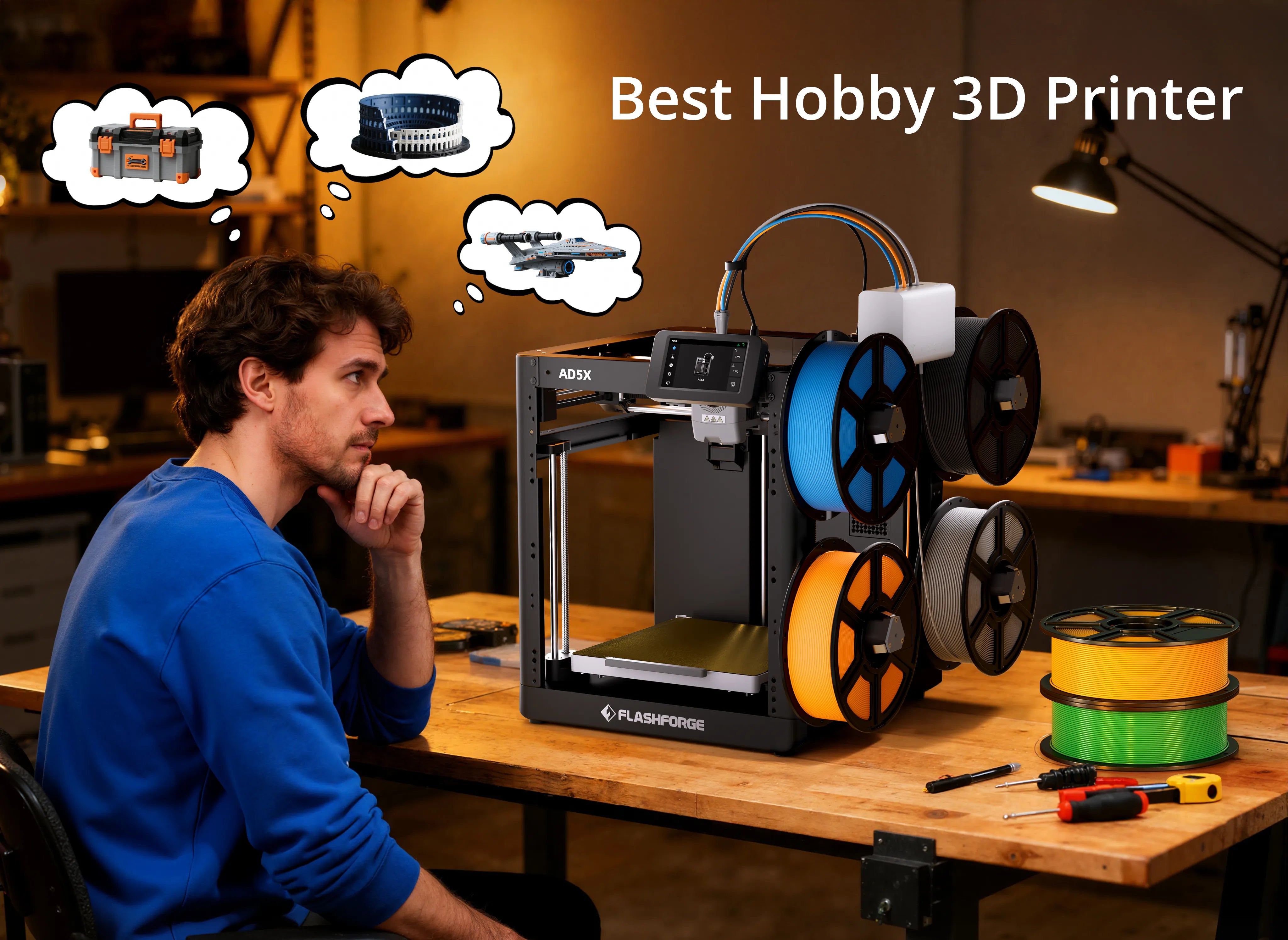

Flashforge AD5X (Multicolour 3D Printer): This model provides "Smart Multi-Colour Printing" in up to four colours, high-speed capabilities, and automatic filament switching, which is ideal for creating vibrant, multi-coloured toys.

-

Flashforge Adventurer 5M Pro: Featuring an enclosed design, a built-in camera, and an air filter, this printer ensures safe printing, even with materials like ABS. It also supports remote monitoring, adding convenience and safety to your FDM workflow.

Key Printer Features to Look For

Beyond specific models, consider features such as build volume, print speed, material compatibility, and ease of use when choosing an FDM printer for toys.

Essential Tips for Successful 3D Printed Toys

To ensure your FDM 3D printed toys turn out as intended, consider these tips:

Material Considerations for Durability and Safety of 3D Printed Toys

The durability of FDM 3D printed toys largely depends on the filament used. While PLA is strong, it can become brittle. ABS is more durable and impact-resistant, making it a better choice for toys that will be handled roughly. For toys meant for water play, ABS offers more water resistance than PLA, though specialised waterproof coatings or filaments may be necessary. When designing for FDM, it's also important to consider the thickness and infill settings to enhance the structural integrity of the final toy.

Optimizing Print Settings for Your Cool Toys to 3D Print

Optimizing print settings is crucial for successful FDM results. For instance, some models like the Flexi Fat Dragon are designed to print without supports, simplifying the process and reducing post-print cleanup. For models that do require support, ensure your slicer settings provide strong bed adhesion and smooth lift speeds to protect delicate parts. Adjusting layer height, print speed (slower often means higher quality), and infill percentage will also significantly impact the final quality and strength of your FDM toy.

Community and Resources for 3D Printer Files

The 3D printing community offers vast resources. Websites like Makerworld.com, Printables.com, Thangs.com, Thingiverse, and MyMiniFactory provide extensive catalogues of STL and 3MF files for FDM printing. 3MF files are particularly beneficial for FDM as they can contain colour layers and part separations, assisting with multi-colour printing on compatible FDM machines.

Addressing Common Challenges with 3D Printed Toys

While FDM 3D printing offers numerous advantages for toy creation, some challenges should be addressed:

Managing Print Time for Complex 3D Printed Toys

Print time can be a significant factor. Depending on the toy's complexity, size, and chosen print speed, FDM printing can take anywhere from 30 minutes for small items to several hours, or even days for large or highly detailed models.

Handling Post-Processing Requirements

Many FDM prints require additional post-processing. This can include removing support structures, sanding rough edges, and painting, which can be time-consuming. However, models designed to print without supports can significantly reduce this workload.

Legal Aspects of Selling 3D Printed Toys

If you intend to sell FDM 3D printed toys, it is generally legal to sell your own original designs. However, if your design is based on copyrighted material (e.g., characters from movies or video games), permission from the copyright holder is typically required. Always be aware of the legal implications before commercializing 3D printed items.

Conclusion

As a beginner-friendly method of 3D printing, FDM 3D printing offers an exciting and accessible way to create custom toys that are both fun and educational. From action figures to personalized action figures, the possibilities are endless. By understanding the basics of FDM printing, experimenting with different designs and materials (such as PLA, ABS, and TPU), and using a Flashforge FDM printer, people can create unique toys for personal enjoyment, as gifts, or even to start a business. Come and get started and print your first 3D printed toy.