What Is FDM 3D Printing? Fused Deposition Modelling (FDM) 3D printing is a process in modern additive manufacturing that builds solids by layering materials. As a giant in the 3D printing market, FDM 3D printing is fundamentally different from manufacturing technologies such as mechanical processing and resin 3D printing. The additive properties of FDM, often combined with soluble support materials, significantly simplify the manufacturing of components with complex geometries and internal cavities. Today's article will take you on a deep dive into what FDM 3D printing is.

FDM: The Foundation of Modern 3D Printing Technology

The term FDM is frequently used interchangeably with Fused Filament Fabrication (FFF), representing the open-source counterpart of the same underlying process. The distinction primarily stems from historical and branding considerations, with no functional difference between the two. FDM stands as the most popular and widely adopted 3D printing technology globally, commanding the largest installed base of 3D printers across numerous industries. Its widespread appeal is rooted in its inherent simplicity, reliability, and ease of operation, making it an accessible and scalable solution suitable for both novices and seasoned industrial users.

The Story of FDM: From a Toy Frog to Industrial Powerhouse

While the journey of FDM from its conceptualization as a method to create a toy frog to its current status as an industrial powerhouse is a compelling narrative, detailed historical content for this specific outline section is not extensively provided within the current resources. Nevertheless, its evolution underscores a remarkable transition from early applications to a critical role in advanced manufacturing.

How FDM 3D Printing Works

The operational principle of an

FDM 3D printer involves depositing melted thermoplastic filament layer by layer onto a build platform until a complete part is formed. The process begins with a digital 3D model, which is electronically segmented into discrete layers by specialized software. A spool of thermoplastic filament is loaded into the printer, which then feeds the material through an extrusion head and nozzle once the nozzle reaches its optimal temperature.

This extrusion head operates on a three-axis system (X, Y, and Z), enabling precise movement across the build area. Molten material is extruded in fine strands, deposited along a predetermined path for each layer. Upon deposition, the material rapidly cools and solidifies. Multiple passes are typically required to fill an entire area within a layer. Once a layer is complete, the build platform descends (or the extrusion head ascends) to prepare for the subsequent layer, a process that repeats until the object is fully realized. Cooling fans may be attached to the extrusion head to expedite material solidification in certain instances.

Adjustable process parameters in FDM systems include nozzle and build platform temperatures, build speed, layer height, and cooling fan speed. While expert operators typically manage these, designers should consider factors such as build size and layer height.

Desktop 3D printers commonly feature a build size of 200 x 200 x 200 mm, like

Flashforge Adventurer 5M Pro 3D Printer, whereas industrial machines can achieve volumes up to 1,000 x 1,000 x 1,000 mm. Larger models can be segmented into smaller parts for printing on desktop machines and subsequently reassembled. FDM layer heights generally range from 50 to 400 microns.

Printing shorter layers yields smoother parts with enhanced accuracy for curved geometries, while taller layers facilitate faster, more cost-effective production. A recommended compromise for optimal results is a layer thickness of

200 microns.

Key Characteristics of FDM 3D Printing: Advantages and Disadvantages

FDM technology is distinguished by a compelling balance of benefits and certain limitations, which are crucial for informed application decisions.

Why Choose This 3D Printing Technology?

Cost-Effectiveness

FDM stands as the most cost-effective additive manufacturing technology available for custom thermoplastic parts and prototypes. It offers significant efficiencies over conventional manufacturing methods, leading to reduced production costs. Desktop FDM provides the most economical entry point.

Material Versatility

A significant advantage of FDM is its

broad and versatile material portfolio, encompassing a wide spectrum of thermoplastics. This ranges from common commodity plastics to engineering-grade materials and high-performance polymers, enabling diverse applications. Each

filament type provides distinct properties, such as strength, flexibility, and temperature resistance, allowing for tailored material selection.

Quick Turnaround

FDM facilitates shorter lead times and quick turnaround for parts. Custom part production with FDM is relatively swift, often taking only a few days. This expedites market entry for products.

Ease of Use

FDM is recognized as one of the easiest 3D printing technologies to learn and operate. Its simplicity and reliability make it a beginner-friendly and scalable solution.

Reduced Material Wastage

As an additive manufacturing process, FDM builds objects layer by layer. This inherent characteristic inherently leads to reduced material wastage compared to subtractive manufacturing techniques that remove material.

Multi Colour Printing

While "

Multi Colour Printing" is noted as a characteristic of FDM in one outline, the specific mechanisms and practical applications of how FDM achieves this are not detailed within the provided resources.

FDM Disadvantages and Limitations

Despite its strengths, FDM presents certain limitations:

Lower Resolution and Surface Finish

FDM generally possesses the lowest resolution among 3D printing technologies, making it less suitable for parts requiring very fine details. Prints typically exhibit visible layer lines and a wavy surface due to the extrusion profile, often necessitating post-processing for a smooth finish.

Warping

Warping is a common defect in FDM, occurring when extruded material cools and shrinks at different rates, creating internal stresses that pull underlying layers upward. This is particularly prevalent in large, flat areas or sharp corners.

Support Structures: FDM printers cannot deposit molten thermoplastic in thin air, meaning support structures are often required for complex geometries with overhangs. While dissolvable supports exist, their use typically increases the overall cost of a print. Removing supports can also add to post-processing time.

Anisotropy

FDM is inherently anisotropic, meaning the mechanical properties of a part can vary depending on the print orientation relative to the layers. This characteristic can make it unsuitable for certain mechanically critical components where uniform strength in all directions is paramount.

Minimum Feature Size

The ability to produce small features is constrained by the layer height and nozzle diameter. Vertical features (Z-direction) cannot be smaller than the layer height (typically 0.1 - 0.2 mm), and planar features (XY-plane) cannot be smaller than the nozzle diameter (0.4 - 0.5 mm). Walls typically need to be at least 2 to 3 times the nozzle diameter (i.e., 0.8 - 1.2 mm).

FDM Materials: Powering Diverse Applications

One of FDM's most significant advantages is its extensive range of compatible materials, allowing users to tailor prints to specific application requirements.

Common FDM Filaments for Everyday Use

For desktop FDM printers, commodity thermoplastics are widely utilized:

-

PLA (Polylactic Acid): The most common material for desktop FDM printers due to its ease of printing and ability to produce parts with excellent visual quality and finer details. However, it exhibits low impact strength.

-

ABS (Acrylonitrile Butadiene Styrene): Offers good strength and temperature resistance, but is more susceptible to warping, especially without a heated print chamber.

-

PETG (Polyethylene Terephthalate Glycol): Comparable to ABS in composition, it is easy to print, food-safe, and possesses good strength.

-

Nylon (PA - Polyamide): Characterized by high strength, excellent wear, and chemical resistance, though it has low humidity resistance.

-

TPU (Thermoplastic Polyurethane): Known for its high flexibility, although it can be challenging to print accurately.

These materials are suitable for a broad spectrum of applications, from prototyping and form, fit, and function testing to low-volume production of models or functional parts.

Advanced FDM Materials for Industrial Strength and Specialization

Industrial FDM machines leverage engineering-grade and high-performance thermoplastics. These often incorporate additives to enhance properties such as impact strength, thermal stability, chemical resistance, and biocompatibility, catering to demanding industrial requirements.

-

ABS (Acrylonitrile Butadiene Styrene): Also used in industrial settings, often with enhanced properties.

-

PC (Polycarbonate): A robust engineering thermoplastic.

-

PEI (Polyetherimide), including ULTEM™ Resins: Offers excellent strength-to-weight ratio, as well as superior fire and chemical resistance, making it ideal for demanding applications despite its higher cost. ULTEM™ 9085 Resin is a notable example of a PEI polymer.

-

PEKK-based Materials (e.g., Antero 800NA): These materials exhibit low outgassing characteristics alongside superior mechanical properties.

-

Carbon Fiber Materials: The addition of chopped carbon fibers significantly enhances stiffness and strength. Examples include FDM Nylon 12CF (one of the stiffest FDM thermoplastics) and ABS CF10, which create stronger, stiffer versions of their base polymers. These are particularly valuable for robust prototypes, jigs, fixtures, and tooling, especially in sectors like automotive and aerospace.

Where Is FDM 3D Printing Used? Real-World Applications

The versatility, ease of use, and extensive material selection of FDM technology position it as a preferred resource across all major industries. It offers time and cost-efficient alternatives to traditional manufacturing methods in sectors such as aerospace, automotive, medical, education, and consumer products.

Rapid Prototyping and Concept Models with FDM

Rapid prototyping is a foundational application for FDM technology. Its ease of use and ability to produce durable prints make it ideal for creating concept models and functional prototypes quickly. This allows engineers and designers to validate concepts and conduct functional testing efficiently during product development.

FDM for Jigs, Fixtures, and Manufacturing Aids

FDM technology provides a faster and more economical method for producing essential manufacturing aids, including jigs, fixtures, and tooling. Durable FDM materials, particularly those reinforced with carbon fibre, are well-suited for creating ergonomic and agile tooling. Examples include composite tooling, which can be produced faster than conventionally made alternatives.

Low-Volume Production and Specialized FDM Parts

FDM technology makes the production of low-volume and out-of-production spare parts economically feasible. It is increasingly utilized for end-use components across various industries. This includes highly specialized parts that might be costly or time-consuming to produce with traditional methods.

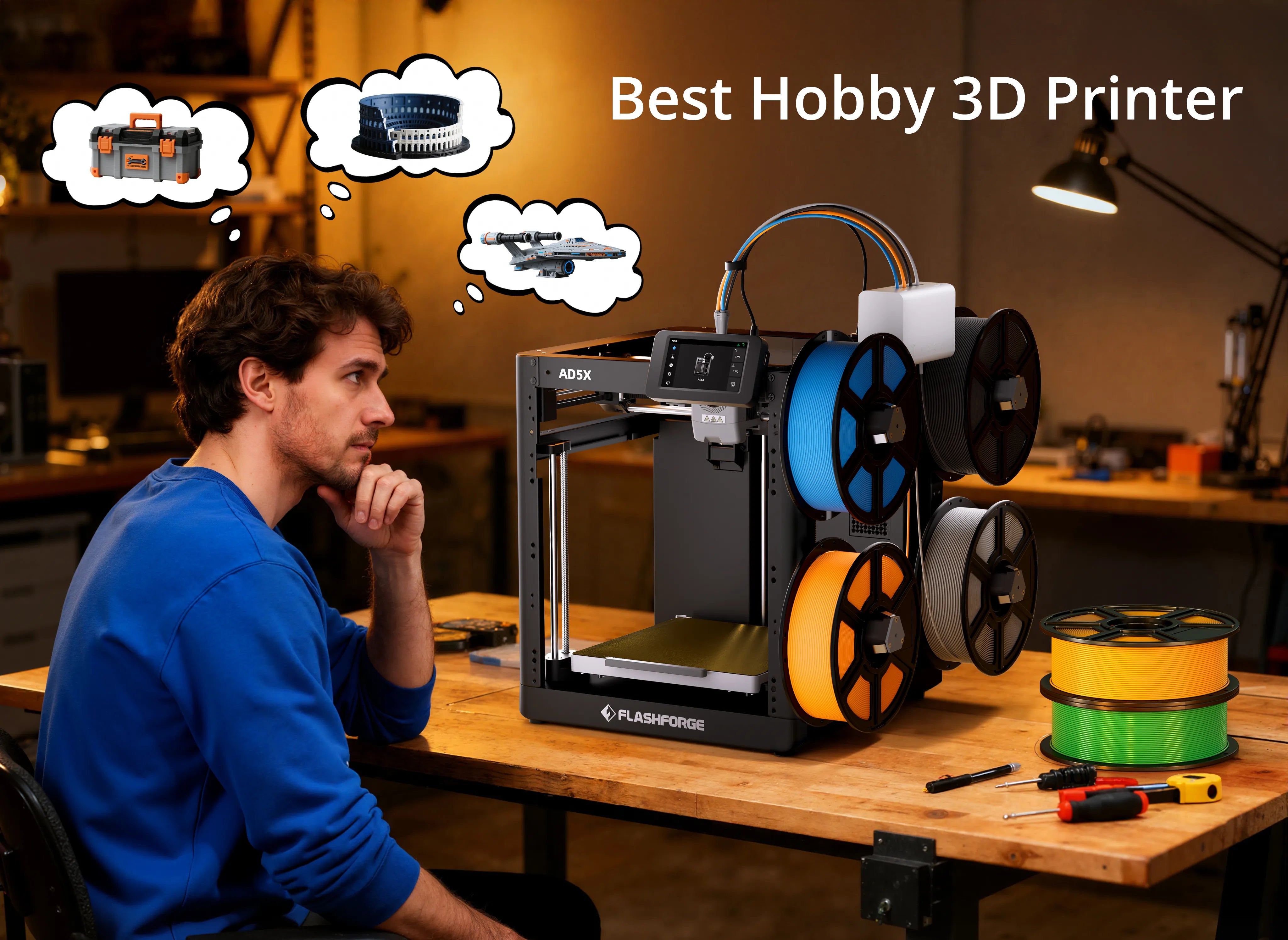

Desktop vs. Industrial FDM: Choosing the Right Printer

FDM printers generally fall into two distinct categories: desktop (prototyping) and industrial (professional) machines, each serving different scales of production and application requirements.

Desktop FDM: Accessibility and Entry-Level Printing

Desktop FDM printers are typically more accessible and represent an entry-level option, largely catering to consumer and at-home use.

-

Cost: Machine costs range from $250 to $2,000

-

Build Volume: A common build size is around 200 x 200 x 200 mm.

-

Maintenance: These machines generally require frequent user maintenance and regular calibration.

-

Materials: Commonly used materials such as PLA, ABS, and PETG.

-

Accuracy: Standard accuracy is typically ± 0.5% (with a lower limit of ± 1.0 mm).

-

Layer Thickness: Typical layer thickness ranges from 0.10 to 0.25 mm.

-

Support Material: Often uses the same material as the part itself for support structures.

Industrial FDM: Precision, Reliability, and Scale

Industrial FDM printers, exemplified by Stratasys 3D printers, are engineered for

precision, reliability, and large-scale production.

-

Cost: About $2,000 and up.

-

Build Volume: They offer significantly larger build envelopes, such as 900 x 600 x 900 mm or even 1,000 x 1,000 x 1,000 x 1,000 mm.

-

Efficiency: Designed for repeatability and reliability, they can complete larger orders faster and produce consistent parts with minimal human intervention.

-

Applications: Primarily used for tooling, functional prototypes, and end-use parts in professional and factory floor environments.

-

Materials: Compatible with a versatile range of engineering-grade thermoplastics (e.g., ABS, PC) and high-performance polymers (e.g., ULTEM™). Carbon fibre reinforced materials are also available for industrial applications.

-

Accuracy: Exhibits higher standard accuracy, typically ± 0.3% (with a lower limit of ± 0.2 mm).

-

Layer Thickness: Typical layer thickness ranges from 0.18 to 0.5 mm.

-

Support Material: Often utilize water-soluble or break-away support materials, which are easier to remove.

FDM Compared to Other 3D Printing Technologies: SLA and SLS

When selecting a 3D printing technology, comparing FDM with other prominent methods like Stereolithography (SLA) and Selective Laser Sintering (SLS) is essential, as each excels in different areas.

Print Quality and Accuracy: FDM vs. SLA vs. SLS

-

FDM: Generally known for its lower resolution compared to resin-based methods, resulting in visible layer lines and a less smooth surface finish. While functional and visually acceptable when well-tuned, it may require significant post-processing for aesthetic applications. Dimensional tolerances typically range between ±0.1 mm and ±0.3 mm.

-

SLA (Stereolithography): Utilizes light to cure liquid resin, allowing for smoother, more detailed results and finer surface finishes. SLA often surpasses FDM in terms of detail and aesthetic quality.

-

SLS (Selective Laser Sintering): While details on SLS print quality are not extensively provided in these FDM-focused sources, it is generally known for producing strong, functional parts with good mechanical properties and isotropic strength due to its powder-bed fusion nature.

Cost, Speed, and Material Considerations

| Feature |

FDM (Fused Deposition Modeling) |

SLA (Stereolithography) |

SLS (Selective Laser Sintering) |

| Cost |

The most cost-effective option, with low equipment and material costs making it very accessible. |

Generally higher equipment and material costs compared to FDM. |

It can be very cost-efficient for batch production, as the cost per part drops with more items printed at once. |

| Speed & Workflow |

Practical and fast for producing functional parts and prototypes quickly. |

While capable of fine detail, the process involves longer cleanup times and complex handling. |

Balances efficiency and complexity, making it suitable for producing functional parts. |

| Material Considerations |

Utilizes a wide range of thermoplastic filaments (e.g., PLA, PETG, ABS). |

Employs liquid photopolymer resins. |

Uses powdered polymers, such as PA12 and PA11. |

Tab.1 FDM vs. SLA vs. SLS: A Technology Comparison

In summary, FDM excels in practicality, speed, and cost-effectiveness for functional parts and prototypes, while SLA is preferred for high resolution and aesthetic finishes, albeit at a higher cost.

Mastering FDM: Expert Tips and Best Practices

Achieving optimal results with FDM 3D printing requires attention to design, post-processing, and printer maintenance.

Designing for Optimal FDM Results

Careful design choices can significantly enhance print quality and prevent common defects:

-

Layer Height Optimization: While FDM layer heights vary, a smart compromise is often to print layers 200 microns thick to balance smoothness, accuracy, and print speed.

-

Preventing Warping: Warping, caused by differential cooling, is a common FDM defect. To mitigate this:

-

Monitor Temperature: Maintain precise control over the FDM system's temperature, particularly the build platform and chamber.

-

Increase Adhesion: Enhance adhesion between the part and the build platform.

-

Design Modifications: Avoid large, flat areas as they are more prone to warping. For thin protruding features, add extra guiding or stress-relieving material at the edges to increase contact with the build platform. Add fillets to sharp corners, as rounded shapes are less susceptible to warping. Note that materials like ABS are generally more sensitive to warping than PLA or PETG.

-

Minimum Feature Size:

-

Vertical Features (Z-direction): Cannot be smaller than the layer height (typically 0.1 - 0.2 mm).

-

Planar Features (XY-plane): Cannot be smaller than the nozzle diameter (0.4 - 0.5 mm).

-

Wall Thickness: Walls should be at least 2 to 3 times larger than the nozzle diameter (i.e., 0.8 - 1.2 mm).

-

Infill and Shell Thickness: FDM parts are typically printed with an outer shell and an internal, low-density infill to reduce print time and save material. Infill and shell thickness significantly influence part strength. A common desktop FDM default is 20% infill density and 1 mm shell thickness, offering a good balance of strength and speed.

-

Support Structures: While supports are often necessary for overhangs, it is generally easier and more cost-effective to design parts to minimize their requirements.

Post-Processing FDM Prints for Enhanced Finish

Due to visible layer lines and wavy surfaces, FDM parts often require post-processing to achieve a smooth finish or to improve aesthetic quality. Available methods include:

-

Sanding and Polishing.

-

Priming and Painting.

-

Cold Welding.

-

Vapour Smoothing.

-

Epoxy Coating.

-

Metal Plating.

For applications demanding ultra-smooth surfaces or extremely fine features, alternative AM technologies like SLA might be more suitable, or extensive post-processing will be essential.

Essential Maintenance and Troubleshooting for FDM

Maintaining FDM printers is crucial for consistent performance. Desktop FDM printers, in particular, require frequent user maintenance and regular calibration. While comprehensive troubleshooting guides are not provided within the resources, the emphasis on temperature monitoring and build platform adhesion for preventing warping indicates key areas of operational vigilance. Effective maintenance ensures the dimensional accuracy and reliability of printed parts.

Conclusion: Is FDM 3D Printing Right for You?

FDM 3D printing stands as a highly accessible, cost-effective, and versatile additive manufacturing technology. Its ability to produce functional parts and prototypes quickly from a broad spectrum of thermoplastic materials makes it an invaluable tool across many major industries.

Overall, however, whether FDM 3D printing is a suitable option depends on your desired 3D printed product. To achieve this, you must balance part quality, material properties, and production volume, while also considering constraints such as budget and time. However, for rapid prototyping, functional testing, custom moulds, and low-volume production of durable thermoplastic parts, FDM offers an excellent balance of usability, material selection, and performance.