As deeply rooted experts in FDM 3D printing, Flashforge maintains a sharp focus on the technological leaps and waves of innovation shaping our industry. In previous posts, we have explored the

Top 10 3D Printing Innovations, analyzed

key Technological Advancements, and discussed the frontiers of

Bioprinting Breakthroughs. Now, as we stand on the threshold of 2026, we are adopting a fresh, forward-looking perspective to unveil the stunning ideas and trends poised to reshape the future.

Industrial Market Growth 2026

According to recent market research data

here, the

global 3D printing market reached approximately $29.3 billion in 2025 and is projected to maintain a Compound Annual Growth Rate (CAGR) exceeding 18% through 2026. This trend is particularly evident in China, where 3D printing investment and financing activities reached a five-year high in 2025, characterized by a distinct concentration of capital among top-tier players. For instance, backed by investors such as Meituan and Hillhouse Ventures, Snapmaker secured tens of millions of dollars in financing. Simultaneously, major brands like Flashforge, Creality (currently sprinting toward a Hong Kong IPO), and Bambu Lab (boasting a valuation exceeding 30 billion RMB) continue to dominate the consumer 3D printer market.

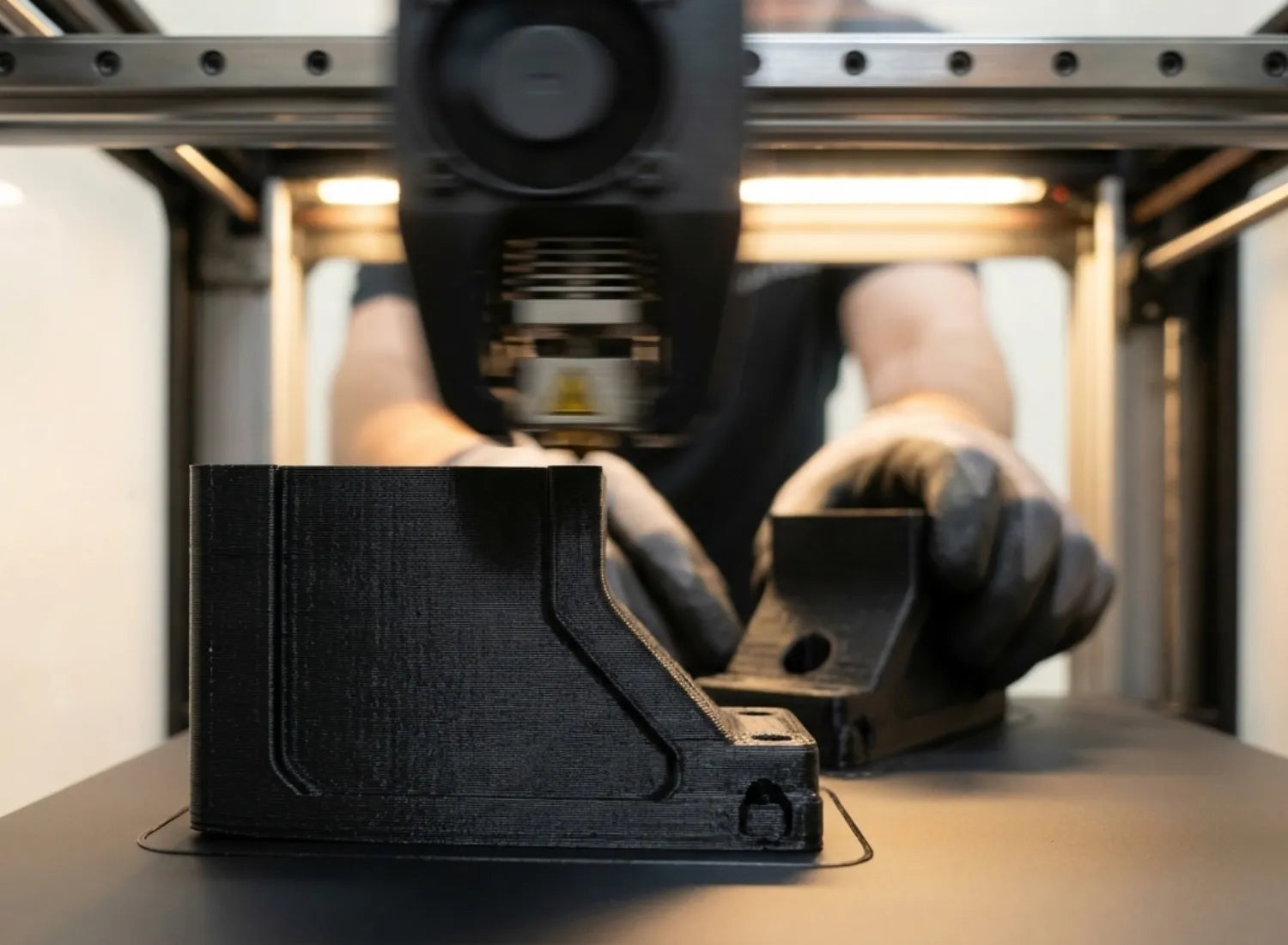

Structural Shift: From Prototyping to Production Tooling

As manufacturing enters a new phase of structural transformation, 3D printing is rapidly evolving from a prototyping tool into a production-critical technology.

Strategic Market Research identifies 2024–2030 as a key growth period for the FDM market, driven primarily by tooling and small-batch production. Although prototyping still represents around 40–50% of market demand, jigs and fixtures are now the fastest-growing application segment.

Compared to traditional CNC machining, 3D printing significantly reduces cost and lead time for complex tooling. This advantage has positioned additive manufacturing as a core asset for enterprises seeking faster time-to-market and greater production agility.

The Rise of Small-Batch End-Use Parts

High-mix, low-volume production has become the new normal for manufacturing in 2026. With increasing print speeds and declining material costs, the direct production of end-use parts is now economically viable. Industry data indicates that demand for small-batch finished components—such as spare parts, brackets, and housings—has transitioned from pilot exploration to routine requirement. For complex parts with annual volumes in the low thousands, 3D printing has proven more cost-effective than injection molding. This trend is especially evident in the consumer electronics, premium home appliance, and customized automotive accessory sectors, where companies are leveraging AM technology to implement zero-inventory production models, manufacturing products strictly on an on-demand basis.

Growth in High-Performance Material Adoption (CF, ESD, PEEK)

Breakthroughs in FDM printing materials science are the core engine driving industrial applications. In 2026, the materials sector is characterized by a dual focus on high performance and sustainability. The adoption rate of high-performance thermoplastics has risen sharply:

-

PEEK & PEKK: In the aerospace and medical implant sectors, these high-temperature, high-strength materials are progressively replacing select metal components, effectively achieving lightweighting goals.

-

Carbon Fibre Reinforced Composites (CF): The maturation of continuous carbon fibre printing technology has enabled printed parts to approach the strength of aluminum alloys. These are now widely used in manufacturing drone fuselages and end-of-arm tooling for industrial robotics.

-

ESD (Electrostatic Discharge) Materials: Demand for anti-static fixtures has surged within the electronics manufacturing industry.

Sustainability Drivers in FDM Manufacturing

Sustainability has become an undeniable driver in FDM (Fused Deposition Modelling) manufacturing. By 2026, the FDM 3D printing industry's focus on closed-loop recycling ecosystems has reached new heights. Recycled and regenerated materials—such as recycled PETG and eco-friendly PLA—along with circular utilization schemes (re-extruding failed prints into filament) are appearing at scale in industrial settings. For instance, startups like Filaret are converting discarded cigarette butts into 3D printing filament, realizing true waste-to-resource utility. Industrial users are beginning to demand verifiable carbon footprint data from equipment manufacturers and are prioritizing printing systems that support bio-based polymers and high-recyclability materials to meet increasingly stringent global ESG (Environmental, Social, and Governance) standards.

Speed and Efficiency Breakthroughs

Speed has historically been the bottleneck limiting the scalability of 3D printing, but in 2026, deep synergy between hardware and software has significantly overcome this constraint. New FDM releases at Formnext 2025 are centred almost exclusively around key themes: multi-colour capabilities, multi-material versatility, high speed, and automation. Consequently, the combination of multi-colour or multi-toolhead configurations with high-speed performance has officially become the new standard for the FDM industry.

Standardization of Ultra-Fast CoreXY Architectures

The CoreXY motion architecture has expanded from the enthusiast community—such as the Voron project—to become the industry standard for industrial-grade high-speed FDM printers. By reducing the inertial mass of moving components, this architecture achieves extreme acceleration (commonly exceeding 20,000 mm/s²) and print speeds (600–1000 mm/s).

Taking Bambu Lab's latest P-series model, the P2S, released in mid-October 2025, as a prime example: this unit is positioned as a comprehensive upgrade to the P1S. It retains the enclosed CoreXY structure while stabilizing maximum print speeds at approximately 600 mm/s. Highlighted by a more stable multi-colour experience and a fully enclosed design, the P2S features an upgraded 5-inch touchscreen, an enclosed chamber with an active carbon filter, and a built-in 1080p camera. With a price point of approximately $549 (or roughly $799 for the Combo set), it successfully targets makers, designers, and prosumers in the $500–$800 budget range, effectively satisfying the mid-market demand for core high-speed capabilities.

High-Speed Print Head and Hardened Steel Nozzle Technology

To complement high-speed motion systems, print heads have undergone a lightweighting revolution. New print head designs integrate compact extruders and high-power heating elements capable of rapidly melting large volumes of filament. Hardened steel nozzles have become standard equipment—for instance, the P2S comes standard with a 300°C hardened steel nozzle. This addresses wear issues caused by abrasive materials such as carbon fibre or glass fibre, significantly extending maintenance intervals and ensuring stability during long-duration continuous production

Reduced Production Cycle Times via Servo-Extrusion

Servo-extrusion technology stands out as a pivotal advancement in 2026. Departing from traditional stepper motors, closed-loop servo motors—such as the upgraded system found in the Bambu Lab P2S—deliver a massive 67% increase in extrusion torque, reaching up to 10kg of pushing force, while monitoring filament flow in real-time. This technology eliminates the risk of missed steps and enables stable extrusion at extremely high volumetric flow rates. The result is a reduction in overall production cycles by more than 30%, directly boosting per-unit throughput.

Mass Production Capabilities

Through clustered management in printer farms, 3D printing is achieving genuine mass production capability. Modern fleet management software now supports the coordinated operation of hundreds of devices, automatically allocating tasks, monitoring status, and detecting faults. When combined with the high-speed technologies mentioned earlier, a single production cell of 50 high-speed printers boasts a daily capacity that rivals traditional small-to-medium injection moulding lines, yet retains a level of flexibility that the latter simply cannot match.

Cost Reduction Through Efficiency

Increased efficiency translates directly into reduced costs. Faster print speeds mean that machine amortization and labour costs allocated to each specific part are significantly lower. Furthermore, the precise control offered by servo motors reduces scrap rates, while AI-assisted slicing software optimizes toolpaths to minimize material waste. All factors considered, the Cost-Per-Part for 3D printing in 2026 has dropped by approximately 40% compared to three years ago, further expanding the technology's application horizon.

Revolutionary Multi-Material Tool Changer Systems

2026 marks a year of architectural innovation for multi-material printing, fundamentally dismantling the historical barriers of nozzle misalignment and excessive material waste.

Lightweight Tool Heads and Rapid Switching (INDX System)

The INDX system from Bondtech represents a lightweight revolution in tool-changing technology. Prusa officially integrated this system into their Core One model, released at Formnext 2025. Through deep collaboration, Prusa and Bondtech have perfectly optimized the INDX Tool Changer for the Core One, supporting 4 to 8 lightweight tool heads. Future iterations on the Core One L (featuring a 300x300x330mm build volume) are set to expand this capacity to 10 heads.

The system utilizes an ingenious smart head plus passive tool architecture. Combined with a CoreXY motion system and the SnapSwap four-nozzle automatic switching system, it enables rapid multi-material printing. This entry of an open-ecosystem multi-tool solution allows for extremely fast and precise tool changes, supporting seamless switching between up to 8 different materials while maintaining ultra-low motion inertia to preserve print speeds. TechRadar notes that this model hits the mid-to-high-end sweet spot between makers, education, and professional prototyping users, offering a maximum rated print speed of around 500mm/s and a build volume of 270x270x270mm.

Automated Hotend Switching for Waste Reduction (Vortek System)

Bambu Lab Vortek system addresses the specific pain point of purging waste in multi-colour printing. With the official debut of the Bambu Lab H2C, the Vortek system has seen real-world application. Building on the H2D foundation, the H2C retains a dual-nozzle architecture while adding the Vortek automated hotend switching system. Traditional single-nozzle multi-colour systems require extruding significant waste to purge the nozzle during colour changes. The Vortek system achieves material switching by physically swapping the entire hotend. This allows for automatic toggling between multiple hotends, significantly reducing the purge piles typical of traditional multi-colour printing. Paired with wireless power and data transmission, the hotends achieve induction heating in seconds, drastically improving multi-colour efficiency. Additionally, for Bambu Lab P2S users, native compatibility with AMS and AMS 2 Pro continues to provide an excellent multi-colour solution.

Multi-Tool Capacity for Material Versatility

These new systems are more about advanced material combinations. Users can combine rigid materials like PLA or PETG with flexible materials like TPU in a single print, or integrate conductive traces within an insulating matrix on the same part. Multi-tool capabilities shatter design limitations, enabling the fabrication of complex functional parts featuring integrated hinges, sealing gaskets, or embedded electronic functions.

Efficiency Gains: 5x Speed Increase and 80% Less Waste

Compared to legacy multi-colour purge tower methods, new systems like INDX and Vortek deliver a dramatic boost in multi-material printing efficiency. Prusa states that its Core One system increases multi-colour printing speed by a factor of five while slashing material waste by approximately 80%. This leap in efficiency transforms multi-material printing from a costly experiment into a genuinely cost-effective production workflow.

Tool Sharing Architecture

Select high-end systems are beginning to support Tool Sharing Architectures, where multiple print heads can be dynamically allocated across different print tasks or zones. This modular design empowers users to configure the machine based on immediate requirements—for instance, deploying two large-bore nozzles for rapid infill alongside a precision nozzle for high-detail perimeters, thereby maximizing equipment utilization.

Emerging Applications of FDM 3D Printing in 2026

From Prototyping to End-Use Manufacturing

The defining development of 2026 is the emergence of Fused Deposition Modelling (FDM) as a truly viable production technology. Once confined to the realms of rapid prototyping and design iteration, FDM is now delivering end-use parts capable of direct integration into commercial products. This shift is underpinned by two fundamental breakthroughs: advancements in materials science and a dramatic reduction in manufacturing costs. Industrial FDM systems now support high-performance polymers with thermal resistance exceeding 200°C, unlocking applications in aerospace and automotive sectors that previously demanded metals or traditional composites. The cost-benefit equation is equally compelling.

The aerospace sector illustrates this transformation most vividly. Industry giants like Boeing, Airbus, and Subaru are leveraging FDM to manufacture functional aircraft components rather than mere prototypes. Part consolidation serves as a prime example of this economic advantage. Engineers have successfully consolidated 73 discrete components into a single integrated unit, simultaneously slashing manufacturing complexity, assembly labour costs, and overall weight. Today, lightweight brackets used to support critical aircraft structures are routinely produced via FDM, directly enhancing fuel efficiency—a quantifiable value driver in the economics of aviation. By 2026, the aerospace 3D printing market is projected to

exceed $6 billion, with FDM technology poised to become the fastest-growing segment for structural and high-temperature component applications.

Unlocking High-Performance Applications

Composite filaments represent the second materials frontier. Carbon fibre-reinforced, glass-filled, and mineral-filled thermoplastics are achieving composite filament market growth rates of 20% annually in the United States alone. These materials deliver weight reduction comparable to traditional aerospace composites while maintaining FDM's design flexibility and tooling economics. Researchers have successfully developed polyamide-based composites modified with electroerosion byproducts from tool steel processing, demonstrating enhanced stress-strain properties across multiple orientations. This multilevel modification approach creates polymer matrix structures that improve performance reproducibility—critical for production applications.

Biocompatible and biodegradable printing materials are emerging as a third category, driven by healthcare demand. Bio-based filaments derived from renewable sources, alongside fully biodegradable polymers like polylactic acid (PLA) variants, are experiencing 25% annual adoption growth. This sustainability dimension directly addresses corporate environmental compliance mandates, particularly in Europe, where CSRD and CSDDD regulations mandate verifiable environmental impact reporting.

Challenges and Considerations for 3D Printing Advancements

Technology Maturation and Adoption Curves

Despite the rapid pace of technological development, bridging the gap between early adopters and the mainstream market remains a significant hurdle. Many traditional manufacturers continue to take a wait-and-see approach regarding reliability and long-term cost-effectiveness. Consequently, we are seeing a flatter adoption curve in more conservative sectors, such as heavy industry.

Patent Landscape and IP Concerns

As digital inventory becomes commonplace, Intellectual Property protection has become an increasingly sensitive issue. Ensuring that digital models are not stolen or replicated without limit during transmission and printing is a shared challenge for the legal and tech communities in 2026. We are gradually seeing blockchain encryption and Digital Rights Management systems being integrated into AM workflows to address this.

Standardization and Regulation

The lack of unified international standards remains a stumbling block for global collaboration. Interoperability between different printer brands, materials, and process parameters is often difficult to achieve. While ISO and ASTM are accelerating the development of testing standards for additive manufacturing, the certification process remains lengthy and expensive, particularly in highly regulated industries like aerospace and medical.

Material Performance Verification

Part anisotropy makes performance verification significantly more complex than with traditional components. The ability to rapidly validate the internal structure and mechanical properties of every printed part using non-destructive testing is a critical quality control puzzle that must be solved for industrial-grade applications.

Long-Term Durability Concerns

Although high-performance materials are available, we still lack decades of historical data on long-term aging, creep, and fatigue characteristics under extreme conditions. This data gap limits the application of 3D printed parts in critical structural components that require a design life of over 20 years.

Supply Chain and Material Availability

While 3D printing reduces dependence on the finished goods supply chain, it shifts that reliance to the supply of high-quality powders and filaments. We are seeing localized tightness in the supply chain for specialized materials in 2026, where raw material price volatility directly impacts the final cost per part.

Recycling Infrastructure and Closed-Loop Ecosystems

The recycling infrastructure for waste prints and support materials is not yet fully mature. Although the use of bio-based materials is on the rise, recycling rates for the vast volume of engineering plastics and composites remain low, making the establishment of a closed-loop material ecosystem an urgent priority.

Conclusion

From our vantage point in 2026, looking back offers a clear perspective. We have moved well past the peak of inflated expectations; the technology has shed the hype to don the armour of true industrial resilience. As we look forward, the integration of AI is the game-changer. It transforms FDM printing from a mere tool into an intelligent engine, one that is destined to reshape the core concepts of how we manufacture and create.