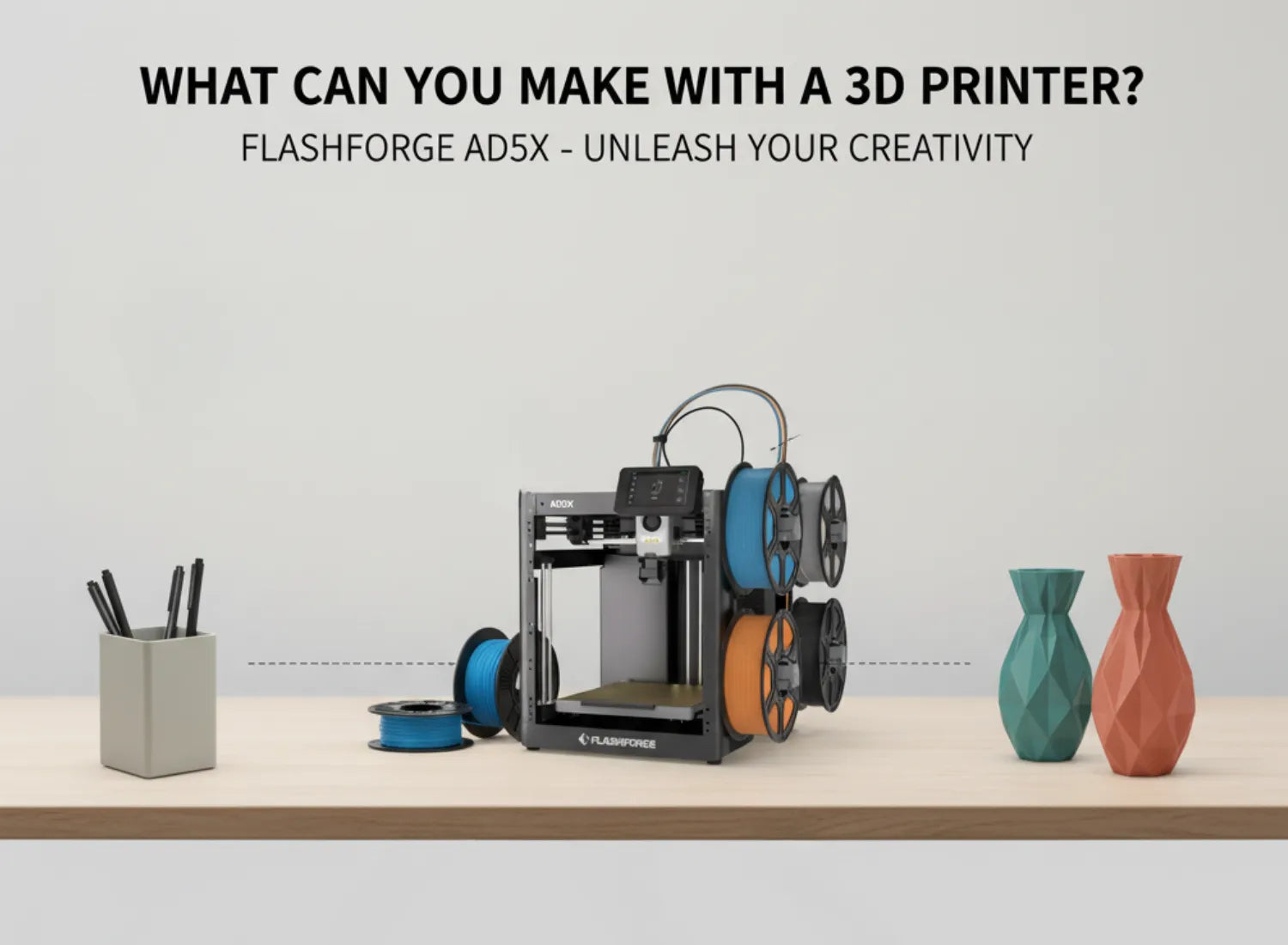

FDM technology has profoundly shifted from its origins as purely rapid prototyping into an essential tool for custom fabrication across numerous industries and creative disciplines. This technology grants creators the ability to materialize three-dimensional projects that were previously costly or functionally impossible to produce affordably.

FDM printers can be utilized to generate both early concepts, allowing designers to review digital designs within hours, and functional, final-use parts for short-run manufacturing. Furthermore, FDM enables the creation of specific tooling, jigs, and fixtures that optimize manufacturing workflows.

A Critical Best Practice: Prior to undertaking any precision-dependent print, it is imperative to calibrate your device to prevent dimensional skew. Utilizing tools such as the Califlower Calibration Tool ensures the printer is set correctly to deliver precise custom fittings.

The following ten categories detail some of the most compelling and high-value objects achievable with FDM technology.

-

Custom Organizers and Storage Solutions

The demand for solutions that mitigate organizational friction in professional environments remains consistently high. FDM printing excels in producing customized, modular, and aesthetic storage elements.

Desk Organizers and Cable Management

The remote work trend has amplified the need for streamlined workspaces.

FDM 3D printers can fabricate items that address common annoyances, leading buyers to frequently purchase these accessories in batches. Products include modular drawer organizers,

Headphone Stands, and various

Cable Winders and Holders to manage tangled cords. The

Honeycomb Storage Wall is an example of a modern, modular organizational solution.

Workshop and Tool Holders

For studio professionals and hobbyists, organizational elements are essential for efficiency. FDM allows for the generation of bespoke sectioned organizers tailored to specific equipment and materials. Specialized components include Solder Spool Stands for electronics work and custom storage for sculpting or painting tools.

-

Kitchen Organization and Tools

Practical and innovative organizational tools for the kitchen remain highly popular and consistently in demand for both sale and personal use.

Utensil Holders and Spice Racks

The versatility of FDM printing enables the creation of custom kitchen organizers that maximize space efficiency. Products include modular utensil holders that can be configured to fit specific drawer dimensions, wall-mounted spice racks with customizable label holders, and countertop tool organizers for frequently used cooking implements. The Stackable Spice Jar System exemplifies a space-saving modular approach to kitchen organization.

Pot Lids and Cutting Board Organizers

For maintaining an orderly cooking environment, specialized holders are essential. FDM allows for the fabrication of bespoke storage solutions tailored to specific kitchen items. These include vertical pot lid organizers that prevent clutter in cabinets, specially designed racks for holding cutting boards upright to preserve counter space, and under-cabinet mounting brackets for paper towels or aluminum foil. A multi-functional design originally created as a kitchen roll holder can be easily adapted to neatly store and dispense plastic wrap or parchment paper.

-

Personalized Gifts and Decorations

Customers actively seek unique and customized products that cannot be acquired from mass-market retailers.

Lithophanes (3D Printed Photos)

Lithophanes, which reveal a hidden image when backlit, represent a popular method for creating personalized, high-value gifts utilizing FDM printing.

Vases and Planters with Unique Geometries

FDM technology is adept at creating intricate, artistic home décor. Vases and Planters featuring complex reticulated or geometric structures provide an aesthetic appeal that is often challenging to replicate using traditional manufacturing methods.

-

Hobby-Specific Prints and Miniatures

Communities dedicated to certain hobbies, such as gaming and niche electronics, are known to be passionate buyers willing to invest in high-quality, custom accessories.

Tabletop Gaming Miniatures and Terrain

While high-detail miniatures are often associated with resin printing, FDM is excellent for producing large-scale pieces like Terrain and Accessories (e.g., buildings, scenery, props). Specific examples include the Library Full Set and Dining Full Set for enhancing immersive tabletop experiences.

Parts for Drones and RC Cars

FDM printers are frequently employed to create custom or replacement components for hobbyist devices like drones and RC (Radio-Controlled) cars, allowing for quick, on-demand maintenance and customization.

-

Educational Models and Tools

Studies have shown that incorporating 3D printing into STEM learning environments not only improves students' understanding of intricate concepts but also boosts their skills in solving problems. 3D printing facilitates hands-on learning by transforming abstract or complex concepts into tangible models.

Anatomical and Scientific Models

The educational sector benefits from the creation of specialized Anatomical and Scientific Models (e.g., solar system models). Specific interactive models include the Brain Puzzle and the Anatomical Heart Puzzle, which demonstrate biological structures with accuracy and interactivity.

Mechanical Toys and Simple Machines

FDM can produce complex,

interactive mechanical toys such as the

Excavator Automata and the

Rock Fans Automata, or

Puzzle cubes. These functional prints demonstrate mechanical principles and push the limits of FDM printing capabilities.

-

Home Repair and Improvement Hacks

The ability to create custom replacement parts represents a profitable opportunity and provides immense value to customers seeking solutions for broken items.

Replacement Knobs, Latches, and Brackets

FDM printers like

Flashforge AD5X 3D printers are essential for manufacturing

Replacement Knobs, Latches, and Brackets for household appliances or even vintage equipment. This service is highly valuable, as consumers are often willing to pay a small amount for a custom part rather than paying significantly more to replace the entire item.

Custom Wall Mounts and Hooks

FDM allows for the creation of unique, specialized wall mounts and hooks. Professionals, such as photographers and filmmakers, utilize custom Equipment Wall Mounts to organize gear like lighting equipment, mitigating safety and clutter issues in the studio.

-

Tech Accessories and Upgrades

Given the permanence of remote work environments, items that enhance professional or gaming setups are consistently high in demand.

Headphone Stands and Controller Mounts

Functional desktop accessories, such as Headphone Stands and specialized Controller Mounts, are easily printed and serve both functional and aesthetic purposes.

Webcam Covers and Laptop Stands

Ergonomic and practical accessories for digital work, including Laptop Stands and Webcam Covers, are among the accessories that can be produced efficiently via FDM.

-

Fashion and Wearable Items

3D printing enables the creation of personalized wearable items featuring intricate, lightweight designs that are nearly impossible to achieve via traditional methods.

Custom Jewelry and Keychains

The fashion and jewelry market has embraced 3D printing for pieces like geometric earrings, custom name pendants, and keychains. The Pangolin Bracelet exemplifies a flexible, nature-inspired design possible through this technology.

Buckles and Costume Props (Cosplay)

The vibrant cosplay market drives demand for intricate, custom-fitted pieces. FDM is suitable for producing large, segmented items like armour, masks, and weapons. Notable examples include the Marvel Deadpool Mask and the Alligator Loki Crown.

-

Musical Instruments and Accessories

For audiophiles and musicians, FDM provides solutions for customized gear and unique acoustic devices.

Ocarinas and Whistles

While specific mentions of musical instruments are limited, the technology allows for complex acoustic structures. Relatedly,

3D printing allows an audiophile to

create their own records by converting audio files, which can then be played on a turntable.

Guitar Picks and Instrument Mounts

3D printing can be used to fabricate practical accessories for musicians. Accessories for audio equipment, such as Headphone Stands or phone Amplifiers that increase speaker sound quality, are effective FDM projects.

-

Upgrades for Your 3D Printer Itself

Maximizing the efficiency and reliability of the printing process is crucial for scaling production. FDM users can print tools and upgrades that streamline their workflow.

Fan Shrouds and Filament Guides

While specific examples of FDM printer upgrades are not detailed, the underlying principle of workflow optimization is paramount. Automated processes, such as using

Orca-Flashforge to remotely monitor and manage prints, are critical for efficiency.

Tool Holders and Spool Rollers

Creating internal Tool Holders and organizational components within the studio helps maintain an efficient workflow. Efficiency gains are also realized through best practices like batch printing multiple small items at once to maximize build plate capacity and save time.

Conclusion: Your FDM 3D Printer is a Gateway to Endless Creation

FDM technology serves as a versatile platform that seamlessly bridges the gap between digital design and physical reality, enabling creation across professional, hobbyist, and industrial domains. From its foundational use in rapid prototyping and manufacturing specialized tooling, jigs, and fixtures to producing highly specialized consumer goods and personalized items, the applications are near limitless. If you want to get more 3D printing inspiration, welcome to our channel: https://www.youtube.com/@flashforge3d/shorts.

For individuals or businesses seeking to capitalize on this technology, consistently focusing on functional utility and customization is key. By adhering to critical practices, such as ensuring precise calibration and optimizing production via batch printing and efficient post-processing workflows, FDM users can successfully navigate their creative journey and even establish a profitable venture.