Upon entering a 3D printing workshop, one often encounters a distinct odour. According to research by the National Institute for Occupational Safety and Health (NIOSH), 3D printers release particles at a rate as high as 2×10⁸ to 2×10¹² per minute—a figure 200 to 300 times higher than the particulate count found in ordinary ambient air. These ultrafine particles typically range from 1 to 100 nanometers in size; their microscopic dimensions allow them to bypass the lungs' natural defence mechanisms and penetrate directly into the lower respiratory tract. For anyone who regularly operates 3D printers, understanding the sources and potential hazards of these emissions is the first step toward protecting their own health and that of their family. Therefore, in this article,

Flashforge—the FDM 3D printing expert—will guide you through the causes, effects, and mitigation tips regarding 3D printing emissions.

What Are the Sources of 3D Printing Odour?

The sources of 3D printing odours are multifaceted. Let us delve into the composition of these emissions by analyzing them from both chemical and physical perspectives.

VOC Emissions

Operating 3D printers in a home environment can result in indoor air pollution levels that reach or exceed hazardous thresholds defined by industrial occupational safety standards. Volatile Organic Compounds (VOCs) are organic molecules capable of evaporating and entering the air at room temperature or relatively low temperatures. During the 3D printing process, as plastic filament is heated to temperatures between 200°C and 300°C, various organic components within the material begin to decompose, releasing a variety of VOCs into the surrounding environment.

Ultrafine Particles

Ultrafine Particles (UFPs), defined as microscopic particles with diameters smaller than 100 nanometers, represent one of the most hazardous pollutants emitted during the 3D printing process. Research findings highlight a stark contrast in emission levels: ABS generates an average mass concentration of 3.13 μg/m³, compared to just 1.43 μg/m³ for PLA—meaning ABS emissions are more than double those of PLA.

Additives and Colourants

3D printing filament is far more than just a simple plastic polymer. To optimize performance, customize colours, and improve printability, manufacturers infuse the base resin with a complex array of chemical agents. These additives include plasticizers (for flexibility), stabilizers (to prevent degradation), colourants (various dyes and pigments), antistatic agents, and flow aids.

When subjected to high printing temperatures, these additives do not merely volatilize alongside the base resin; they can also undergo secondary thermochemical reactions, generating additional toxic byproducts. While high-quality filaments typically maintain a purer composition with fewer unessential chemicals, budget-friendly options often rely on heavy loads of inferior additives to cut production costs.

Material-Specific Odours

Different types of plastic filaments release distinct chemical cocktails when heated, resulting in vastly different odour profiles. Essentially, what you are smelling is the direct "signature" of specific Volatile Organic Compounds (VOCs).

Take ABS, for example. Its name alone—Acrylonitrile Butadiene Styrene—reads like an ingredient list. When heated, the primary byproduct released is styrene, a chemical known for its sharp, acrid fumes. That is the culprit behind the unforgettable, pungent smell that fills the room whenever you print with ABS.

On the flip side,

PLA filament (Polylactic Acid) is derived from renewable sources like cornstarch and sugarcane. When it breaks down thermally, it releases relatively benign compounds like lactic acid and lactide. This explains why most users find the scent of PLA to be mild and non-irritating. Sitting somewhere in the middle is

PETG; its thermal decomposition byproducts fall between the two extremes, resulting in an odour that is generally faint and much easier to live with.

Nozzle or Hotend Residue

The 3D printer nozzle (often referred to as the hotend) serves as the critical junction for filament extrusion, maintaining an operating temperature identical to that required for printing. Over time, filament residues inevitably accumulate both within and around the nozzle assembly. These deposits originate from multiple sources: chemical additives within the filament, fragments of incompletely degraded polymers, and carbonized remnants from previous print jobs. Whenever fresh filament is extruded, these accumulated residues are subjected to reheating. As these carbonized or degraded materials undergo thermal cycling, they release acrid odours and additional contaminants. These secondary emissions are often more hazardous than those from virgin filament, as they consist of byproducts resulting from partial oxidation and thermal decomposition. On a neglected nozzle, these residual layers thicken over time, directly correlating with an increase in both malodours and particulate emissions. This explains why experienced 3D printing enthusiasts emphasize the critical importance of

regular 3D printer nozzle maintenance; it is a practice that not only preserves print quality but also significantly mitigates hazardous emissions.

Enclosure Air Build-Up

When a 3D printer is placed in a confined or poorly ventilated space, the issue of emissions escalates rapidly. In such environments, released VOCs and UFPs are unable to dissipate; instead, they continuously accumulate within the confined area. According to measurement studies by Alveo3D, when a printer operates in a closed room without a ventilation system, pollutant concentrations rise sharply and persist at elevated levels for a relatively extended period. Researchers observed on the test bench that, in the absence of air filtration, particle concentrations "rise very rapidly, and this high-concentration state persists for a considerable time before slowly returning to levels approaching ambient atmospheric pollution." This implies that if you print in poorly ventilated areas such as bedrooms, basements, or small offices, you are effectively inhaling air where VOC and UFP concentrations may rise continuously throughout the print job, creating a harmful vicious cycle. Children's rooms pose a particular risk because children have a higher respiratory rate than adults, meaning they inhale a relatively larger volume of pollutants, and their lungs are still in the developmental stage. Therefore, we must exercise great caution when

selecting 3D printers for children.

What Does 3D Printing Smell Like?

Sweet and Mild Scent of PLA Filament

Upon encountering the scent of printing PLA filament for the first time, you may be pleasantly surprised to find it quite tolerable. The aroma emitted during PLA printing is frequently described as mild and slightly sweet, with some users even comparing it to the scent of honey or vanilla. This relatively agreeable olfactory profile stems directly from PLA's unique chemical composition.

Derived from renewable resources such as corn starch or sugarcane, PLA is a natural biopolymer. When heated to approximately 210°C—a relatively low printing temperature—its primary thermal decomposition byproducts are mild organic molecules like lactic acid and lactide. While these particles can still be inhaled, their toxicity profile is significantly lower than the pungent, irritating fumes released by ABS and other petroleum-based plastics.

This characteristic makes PLA the ideal companion for consumer-grade

FDM 3D printers and the most highly recommended material for sensitive environments such as homes, schools, and libraries. It is important to note that while PLA does release Volatile Organic Compounds (VOCs) and Ultrafine Particles (UFPs)—at levels approximately 5 to 10 times higher than background ambient air pollution—these emissions are drastically lower than those of alternative materials. This does not imply that PLA emissions are entirely harmless, and users should still implement basic ventilation measures; however, compared to the alternatives, PLA undoubtedly offers the optimal balance of safety and olfactory comfort.

Strong Plastic Odour of ABS Filament

The odour emitted during ABS printing is distinctively strong and pungent, characterized by the unmistakable scent of burning or melting plastic. Many users encountering ABS fumes for the first time immediately recognize it as an "industrial" odour—one that feels inherently unsuitable for residential or educational environments.

When compared to PLA under identical conditions, ABS releases double the mass of particulate matter and generates exponentially higher levels of VOCs. This significant difference explains why prolonged exposure to ABS printing in poorly ventilated spaces often leads to user complaints of headaches, eye irritation, and respiratory distress.

Slight Chemical Smell of PETG Filament

PETG filament(Polyethylene Terephthalate Glycol) hits a sweet spot between PLA and ABS, and its odour and emission profile sits right in that middle ground, too.

The scent produced during printing is typically described as a "faint" or "slight" chemical odour. While it is nowhere near as aggressive or pungent as ABS, it doesn't quite match the mild, organic profile of PLA. This intermediate characteristic stems from PETG's molecular structure and its printing requirements; it operates at temperatures (around 230–250°C) that are hotter than PLA, yet hover near the lower end of the range used for ABS.

This makes PETG a fantastic middle-of-the-road option: it delivers superior thermal stability and strength compared to PLA—making it perfect for printing functional parts—while keeping emissions and odours relatively low. For users who need durability without sacrificing indoor air quality, PETG is the ideal compromise.

Rubber-Like Aroma of TPU Filament

TPU (Thermoplastic Polyurethane) is the go-to flexible filament for creating parts that require elasticity and resilience. Its odour profile is typically described as mild, carrying faint notes of rubber or organic solvents. Unlike the harsh assault of ABS fumes, TPU typically doesn't trigger immediate physical discomfort—but do not mistake that for total safety.

Research indicates that when heated, TPU releases specific Volatile Organic Compounds (VOCs), notably cyclic methyl siloxanes (specifically D4, D6, D7, and D8). While TPU falls into the "medium emission" category—sitting squarely between PLA and ABS—its unique chemical makeup can still pose health risks depending on individual sensitivity.

For makers who need flexibility but want to keep emissions in check, TPU is a significantly better choice than ABS. However, basic ventilation is still a must, particularly during long print sessions or in high-frequency printing environments.

Burning or Unusual Smells

If you catch a whiff of a strong burning smell or any unusual odour during a print, take it seriously—it is usually a sign that something needs your immediate attention.

-

Check for Overheating.

First, consider the possibility of nozzle overheating. If your print temperature is cranked up too high—pushing beyond the filament's recommended range—the material won't just melt; it will undergo pyrolysis and carbonize. This leads to a nasty burnt smell and a massive spike in toxic fumes. We see this frequently with older printers or machines with inaccurate temperature sensors.

-

Inspect Your Filament Quality.

Second, the quality of your filament might be the culprit. Bargain-bin or unbranded spools often contain inferior raw materials or contaminants that release strange odours and harmful substances when heated. Some sketchy manufacturers even cut corners by mixing in unknown recycled plastics or fillers.

-

Clean Out Old Residue.

Third, look out for old residue inside the nozzle. If you haven't cleaned your hotend in a while, built-up carbonized gunk gets reheated every time fresh filament passes through, generating that distinct acrid smell.

-

The Safety Stop.

Finally, and most critically, an unusual smell could indicate that the printer’s electronics or plastic housing are overheating—a potential fire hazard. In this scenario, the smartest move is to hit the stop button immediately, inspect your machine thoroughly, and ensure everything is in perfect working order before you even think about hitting "print" again.

Ventilation Tips for Controlling 3D Printing Odour and Risks

Ventilation is the absolute baseline for controlling 3D printing pollution. The goal is simple: physically remove airborne contaminants from the air you breathe. There are two primary ways to achieve this: Natural Ventilation and Mechanical Ventilation.

Natural Ventilation

This relies on natural airflow to dilute and flush out pollutants. The simplest form is just opening a window while you print.

-

The Reality: It creates a basic draft to carry fumes out, but its effectiveness is hit-or-miss. It depends heavily on wind speed, window size, and your room's layout.

-

The Downsides: On calm, humid days, or during extreme temperature swings, it may not be enough. In winter, opening a window means losing heat and sacrificing comfort.

-

The Verdict: Despite its limitations, natural ventilation is always better than printing in a sealed, stagnant room.

Mechanical Ventilation

Active and Reliable (Recommended) This method involves using fans to force air movement. The most effective setup for home users is an Inline Duct Fan System.

-

The Setup: You connect flexible ducting to your printer’s enclosure (or the immediate printing area) and vent the air directly outside through a window adapter or a wall port.

-

Gear & Cost: Popular commercial options include the AC Infinity Cloudline series, which ranges from mid-range to high-end pricing. A complete DIY installation typically costs between $100 and $300, covering the fan and ducting materials. It requires only basic handyman skills to set up.

-

The Golden Rule: While you could install a heavy-duty whole-room exhaust, localized "spot" ventilation is usually far more cost-effective. The key is to create negative pressure that pulls air out of the print zone, preventing pollutants from drifting into the rest of your home.

The "Maker" Approach: Leverage Your Machine!

Since you are already into 3D printing, don't feel like you have to buy every single accessory! Head over to Printables (or similar 3D printing repositories) to find community-designed ventilation mods. You will find brilliant solutions like custom window exhaust vents, magnetic duct couplers, and fan shrouds designed specifically for your printer model. Printing your own adapters is not just cost-effective; it’s the true spirit of the hobby.

How to Choose Odour-Free 3D Printing Materials

Hunt for Low-Emission Filaments

Ingredient transparency is everything. High-purity filaments—those made from top-tier virgin polymers rather than mystery recycled blends—typically produce significantly fewer emissions.

Check for Material Purity and Additives

Before you hit "buy," make it a habit to pull up the Material Safety Data Sheet (MSDS). Practically every reputable manufacturer provides this. It is your cheat sheet for verifying ingredients, potential hazards, and safe handling protocols.

Other Quality Indicators to Watch For:

-

Colour Uniformity: Unspool a bit and look closely. Premium filament should have a perfectly consistent Colour—no weird streaks, specks, or blobs. Inconsistencies here usually point to poor mixing or low-quality additives.

-

Diameter Consistency: Quality control is king. A good filament should hold a tolerance of ±0.05mm or better.

-

The Price Tag: If a deal looks too good to be true, it probably is. Dirt-cheap filament almost always means corners were cut on raw material purity, which often leads to nastier fumes.

Prioritize PLA and Low-Odour Alternatives

-

Start with PLA: If you want a material that works for 90% of applications with the lowest emissions and the mildest scent, PLA is the undisputed champion.

-

PETG is Your Runner-Up: Need something tougher and more heat-resistant than PLA for functional parts? PETG is the logical step up. It offers greater strength with VOC emissions that are only marginally higher than PLA, keeping the air quality relatively safe.

For Specialty Needs:

Need flexibility?

Look for bio-based TPU rather than standard petroleum-based options.

Need structural strength?

Pick PETG over ABS every time. Before settling for a harsh-smelling material, always do a quick search for a low-emission alternative—chances are, a safer, cleaner option exists.

Review Manufacturer Safety Data

Before finalizing your filament selection, use this safety checklist to ensure you are taking responsibility for your health and the well-being of those around you:

-

Is a Material Safety Data Sheet (MSDS) available? If the manufacturer is unwilling or unable to provide an MSDS, consider this a major red flag.

-

Does the MSDS list specific VOC components? If ingredients are vaguely listed as a "proprietary formula" without further detail, this indicates a lack of transparency.

-

Has the filament undergone third-party emissions testing? Reputable manufacturers often publish emission test reports from independent laboratories to verify their claims.

-

Are there recognized emission certifications? Look for filaments that are certified as "Low Emission" or carry recognized eco-labels.

-

Has the manufacturer published thermal decomposition temperatures? Providing this data demonstrates a commitment to safe handling protocols and technical rigour.

-

Is there feedback from real users regarding emissions? Online communities and forums are valuable resources for user reports on the odour and emission characteristics of specific brands.

-

Is the material virgin or recycled? For the highest safety consistency, prioritize filaments made from virgin materials over those with unknown recycled content.

Critical Red Flags: Be wary of products that exhibit: no MSDS, "proprietary formulas" lacking detail, a total absence of emissions data, suspiciously low pricing, unclear country of origin, or come from unverified new manufacturers. If a filament displays any of these warning signs, it is best to choose an alternative.

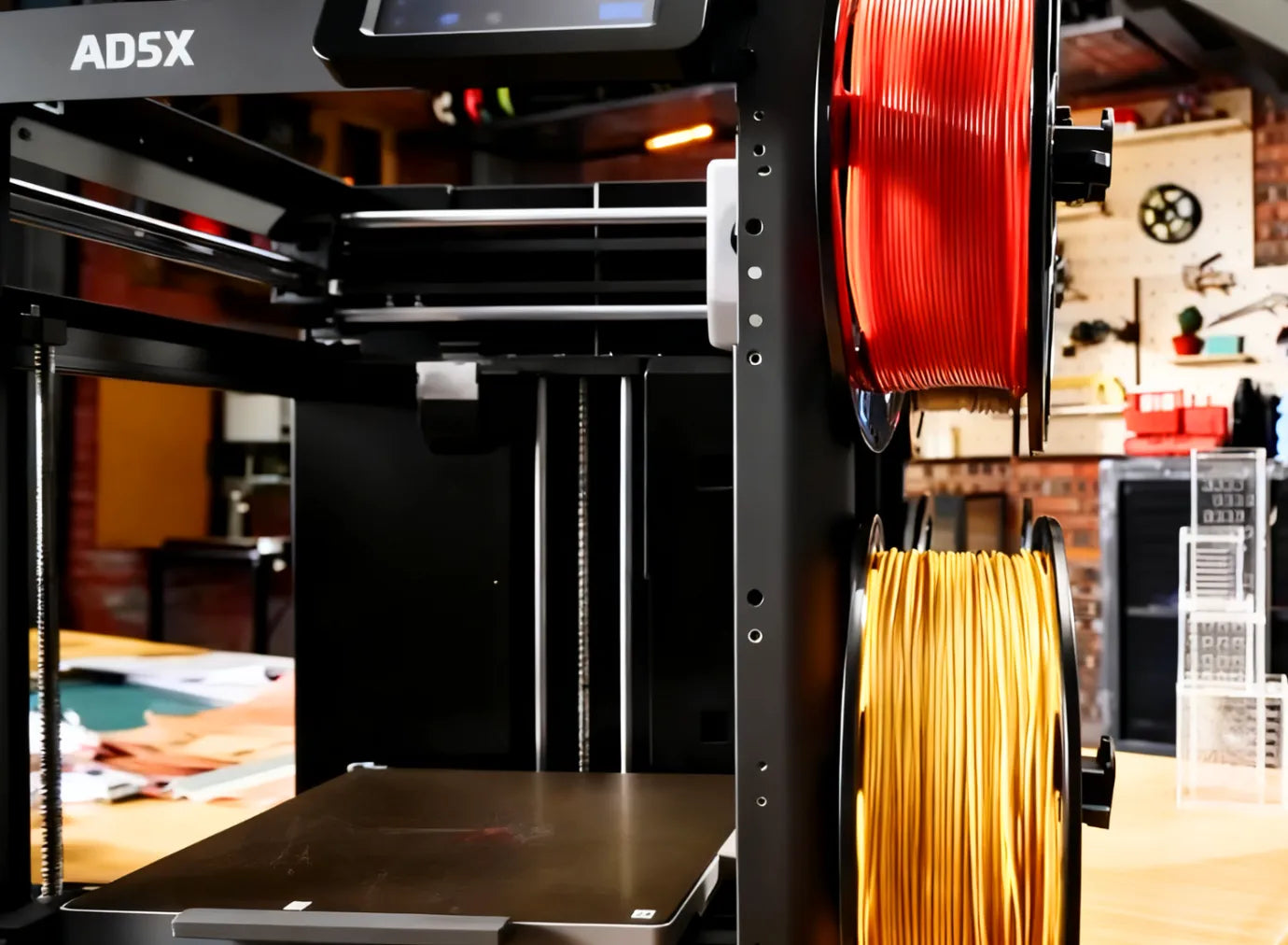

How to Choose an Odour-Free 3D Printer

Look for Fully Enclosed Designs

The physical design of the printer plays a massive role in emission exposure levels. A fully enclosed chamber offers multiple benefits:

Temperature Stability: It maintains a stable internal environment (typically raising the ambient temperature by 10–15°C), which improves reliability when printing high-temperature materials.

Draft Protection: It shields prints from external airflow, such as HVAC systems or open windows, preventing warping.

Pollutant Containment: Most critically, it limits the leakage of emissions into your living area. When an enclosure is paired with a proper ventilation or filtration system, pollutants are effectively captured or vented out rather than drifting freely into the room.

Check for Built-in Air Filtration

When evaluating a printer, scrutinize the filtration specifications:

Efficiency Rating: What percentage of particles does it capture?

Maintenance: Check the replacement cost and lifecycle of the filters—this is a key factor in long-term operating costs.

Structure: Does the system utilize multi-layer filtration?

Noise: How loud is the filtration fan during operation?

Evaluate Ventilation and Exhaust Options

A printer designed with safety in mind should offer flexibility for external venting. Look for:

External Ducting Support: The ability to vent pollutants directly outside rather than recirculating them indoors.

Standard Interfaces: Does it have a standard exhaust port (typically 4–6 inches / 100–150mm diameter)?

Expansion Space: Is there reserved space or mounting points for adding a filtration unit?

Compatibility: Is it compatible with established third-party systems like Alveo3D?

Key questions to ask before buying:

"Does this model support DIY exhaust mods?"

"Are there community-designed filter adapters available?"

"Does the manufacturer offer official exhaust accessories?"

Consider Noise and Thermal Management

Why this matters: High-power exhaust fans can generate significant noise, especially during long print jobs, impacting your quality of life. Furthermore, excessive noise can sometimes indicate inefficient aerodynamic design. Good thermal management ensures the printer maintains stable temperatures without overheating, which is crucial because higher temperatures often correlate with increased emission levels.

Check the Data: Look for standard Decibel (dB) ratings, exhaust fan specifications, cooling system design, and the efficiency of internal airflow paths. If the manufacturer does not publish these specs, it is a detail worth investigating further.

Gather Real-World User Feedback on Odours

Last but certainly not least, never underestimate the value of raw, unfiltered feedback from actual users. The internet is teeming with discussions regarding the specific emission and odour profiles of different printers. You can find a goldmine of information on

Reddit’s 3D printing communities (especially

r/3Dprinting), dedicated industry forums,

YouTube review videos, user reviews on

Amazon and B2B sites, and within various

Discord servers.

Pro Tip: To dig up the most relevant info, try these search combinations:

-

"[Printer Model] + smell"

-

"[Printer Model] + emissions"

-

"[Printer Model] + VOCs"

-

"[Printer Model] + ventilation"

When evaluating reviews, context is king. Keep the following factors in mind:

-

Environment: Was the printer in an open garage or a small, closed bedroom?

-

Ventilation: Did they have an exhaust fan or a window open? This is often the biggest variable.

-

Material: Are they printing PLA (mild) or ABS (pungent)?

-

Frequency: Are they a weekend hobbyist or running a 24/7 print farm?

-

Sensitivity: Remember that some individuals are naturally more sensitive to chemical odours than others.

Consider this scenario: One user might complain about overpowering fumes while printing ABS in a sealed room, while another user with the exact same machine and filament reports minimal odour because they have a proper exhaust setup. Both reviews are accurate—the game-changer is the ventilation.

Conclusion

Yes, 3D printing produces odours, and more importantly, those smells act as a warning sign for real underlying health risks. But here is the bottom line: these risks are entirely manageable with the right approach.

By prioritizing low-emission materials (sticking to PLA or PETG instead of ABS), installing a robust filtration system (HEPA H13 or H14 filters combined with activated carbon), ensuring proper ventilation or external exhaust, and regularly maintaining your machine to prevent residue buildup, you can drastically lower the health risks associated with 3D printing. We also recommend limiting direct exposure to under 40 hours per week and staying vigilant about any physical symptoms.

Opting for a modern, fully enclosed 3D printer, keeping your nozzle clean, reviewing manufacturer Safety Data Sheets (MSDS), and establishing a solid workflow are the pillars of a safe printing practice. For anyone considering jumping into 3D printing or those already part of the community, my advice is simple: educate yourself, invest in the right tools and materials, and prioritize safety. The reward for this effort is the freedom to safely harness the full potential of this incredible technology while protecting everyone who uses it.

FAQ

Q: What exactly is in the "smell" released by 3D printers?

A: It is a complex mix of toxic substances. Research detects Volatile Organic Compounds (VOCs), including known carcinogens like Formaldehyde and Benzene, neurotoxins like Styrene, and Ultrafine Particles (UFPs) containing heavy metals like Lead and Chromium.

Q: How does exposure affect my health?

A:

-

Short-term: Headaches, nausea, fatigue, and irritation of the eyes, nose, and throat.

-

Long-term: Chronic exposure can lead to asthma, respiratory damage, cardiovascular issues, and potentially permanent lung function changes due to oxidative stress and DNA damage.

Q: At what point does the risk become significant?

A: Studies show a clear "exposure-response" relationship. Spending more than 40 hours per week near an operating printer significantly increases the risk of developing respiratory conditions like asthma or rhinitis.

Q: Are children at higher risk?

A: Yes. Children are the most vulnerable because their lungs are still developing and they breathe faster than adults. For family or classroom use, we strongly recommend fully enclosed printers with built-in filtration systems, such as the

Flashforge AD 5M Pro 3D printer, to contain emissions.

Q: What physical symptoms are warning signs?

A: Do not ignore persistent coughing, wheezing, chest tightness, recurring headaches, or skin rashes. If you or your family experience these symptoms, stop printing immediately, ventilate the area, and consult a doctor.