The concept of a 3d printed 3d printer has been a hot topic for engineers, makers, and researchers for over a decade. The idea is a frontal challenge to the conventional manufacturing process, proposing a future in which the 3D printer can fully reproduce itself, or at least partially. As better materials and hybrid production methods continue to develop for additive manufacturing, we have never been so near to knowing what a 3D printed 3D printer might look like in reality.

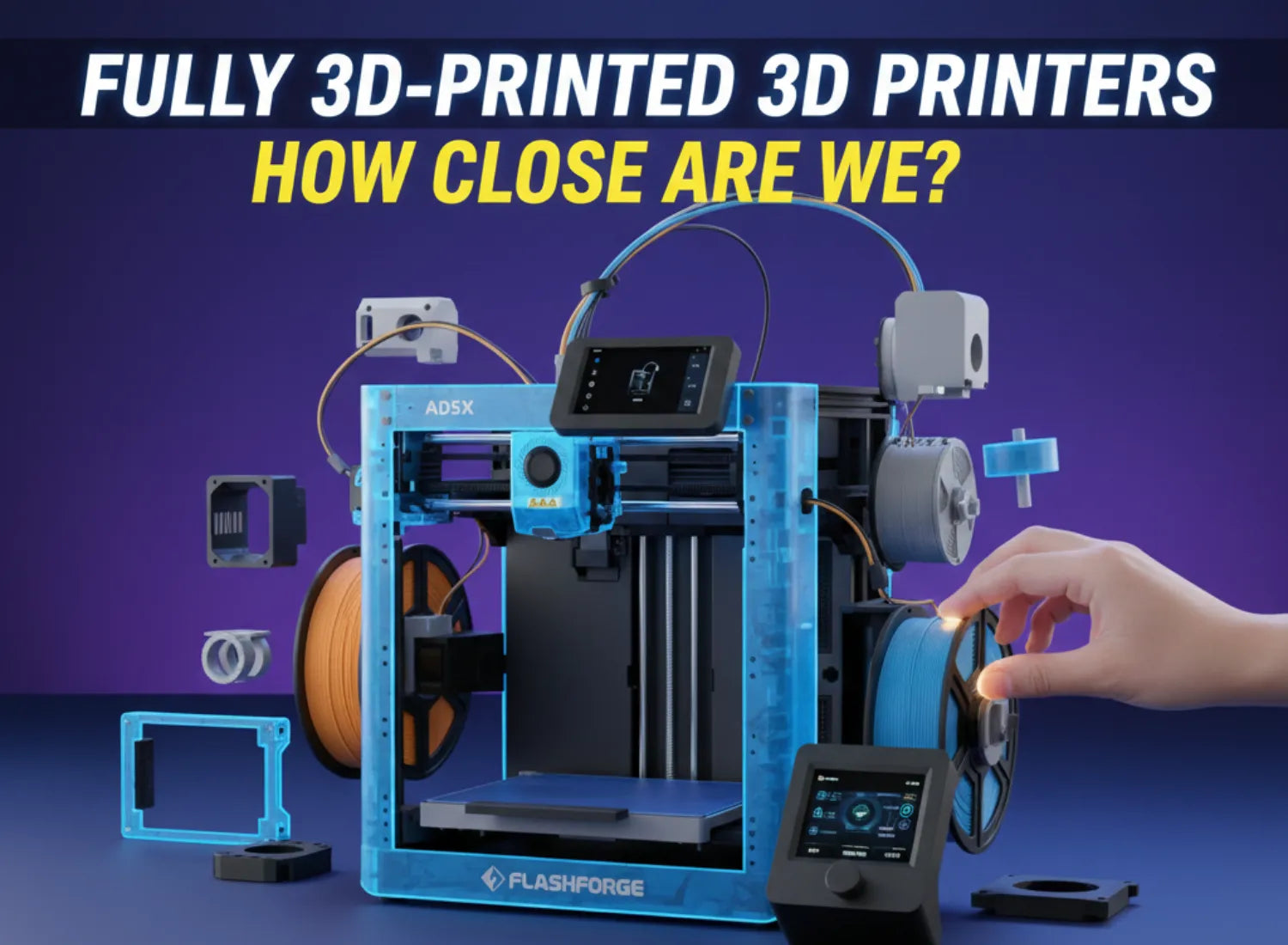

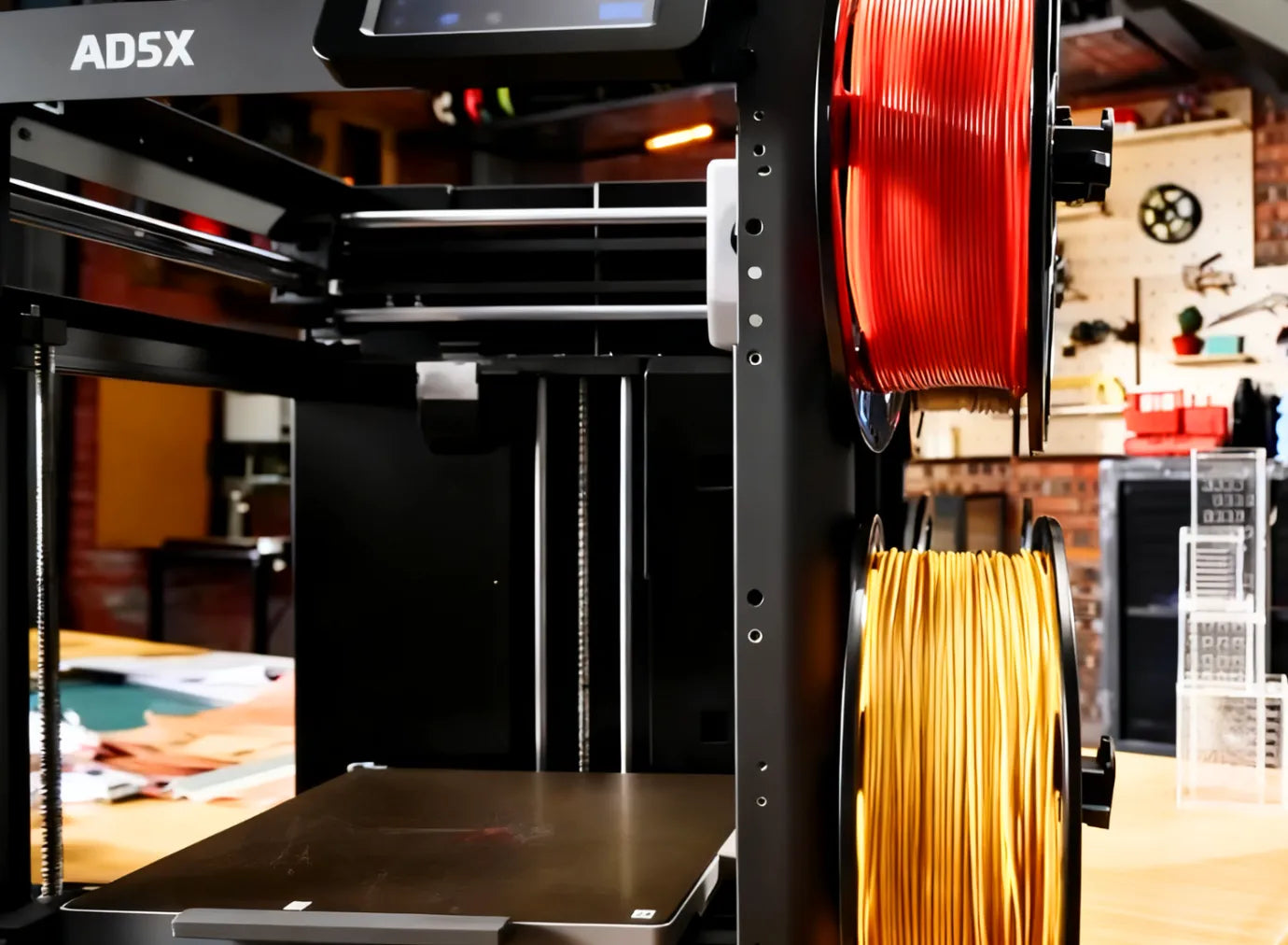

Prior to discussing possibilities, challenges, and recent research, it should be mentioned that the present 3D printing technology is rapidly advancing. The latest models, like the AD5M Pro, are already pushing the limits of high printing speeds, high precision, and even material compatibility. But even these high-tech machines show us that we still have a long way to go before we have a fully 3D printed 3D printer.

What Does Fully 3D Printed Actually Mean?

The term “fully 3D printed” implies that nearly, if not all, the components of an

FDM 3D printer, including structural, mechanical, electrical, and functional, can be made using 3D printing alone.

This is an incredibly high bar to achieve, as it’s so much more complicated than printing simple parts and components where tolerance is more relaxed. The 3D printing machine responsible for the production has to be capable of manufacturing parts that can meet even precise machinery standards for motors, wiring, and sensors; the parts also need to meet durability standards and be resistant to heat, and to be “fully 3D printed”, even the processors of the machine have to be made using 3D printing.

All the aforementioned parts require disparate expertises. If we can condense all the knowledge and all the capabilities of different fields into one competent 3D printing machine, it would be a major breakthrough in automated manufacturing.

Which Parts of a 3D Printer Can Already Be 3D Printed

Before delving into the specific ingredients, it is useful to know how existing printable components are integrated into the overall design of a contemporary 3D printer. The major categories that can already be manufactured through additive manufacturing are given below.

Most structural components, such as frames, brackets, enclosures, fan ducts, tensioning of belts, and covers, are often created through

FDM or resin 3D printers. Such components can be easily printed since they typically do not involve complicated electrical or thermal functions, but only need shape and stiffness. Structural components that are printed are already common with DIY printer kits.

3D Printed Mechanical Elements

The 3D printing of gears, pulleys, knobs, bearing housings, and other high-strength materials such as nylon,

PETG filament, or carbon-fibre-reinforced filaments is effective. Although they might not be as strong as their metal counterparts, they hold when used in low to medium-stress applications.

Partially Printed Motion Systems and Tool Heads

Some enthusiasts have tried to print linear guides, belt clamps, or even part bodies of the extruder. These components are often used to the point of failure due to friction and exposure to heat, although they remain functional. Nozzles of metal, heaters, thermistors, and precise management of temperature are typically necessary for the tool heads, which are also still out of reach of printable materials.

The Parts That Still Require Conventional Manufacturing

Even with the significant advances in 3D printing, some vital parts of printers continue to depend on conventional manufacturing processes. These restrictions underscore the technological inadequacies that prevent a fully 3d printed 3d printer.

Electronics, Motors, and Sensors

Electronic core components, PCBs, stepper motors, wiring, microcontrollers, and sensors cannot be 3D printed currently on a consumer or industrial scale. These components need metallic conductors, semiconductors of silicon, and fabrication processes such as photolithography.

Precision Components and Heat-Resistant Parts

Metal rails, ball bearings, hardened nozzles, heat breaks, and other components of extruders that operate at high temperatures are made with materials that can withstand hundreds of degrees Celsius while intense mechanical force is being applied to them. Plastic filaments cannot possibly substitute these components without severe performance loss.

Material Compatibility and Tolerance Issues

Most 3D printers demand assembly precision on a micron scale. Printed components tend to shrink or distort based on orientation. Critical parts will have to be traditionally produced until the day when 3D printers can print with zero tolerance error.

Current Research and Experimental Progress of 3D Printed 3D Printers

The current barriers are being addressed by researchers working all around the world. Other emerging technologies are bringing 3D printing nearer to self-replication.

Advances in Multi-Material Printing

Scientists are working on hybrid printers that have the ability to print metals, ceramics, and polymers simultaneously. An experimental multi-material system has the potential to print integrated structures that offer rigidity, flexibility, and basic conductivity, and a step towards a functional 3D printed 3D printer.

3D Printed Electronics and Embedded Circuits

Advances in conductive inks, printed circuit traces, and embedded wiring systems are indicators of a significant change in the way electronics will be made. Methods such as aerosol jet printing or hybrid deposition can, one day, possibly enable circuit partial printing, but they are not yet capable of substituting PCB production.

Open-Source Innovation and Community Prototypes

The RepRap project introduced the concept of a printer that replicates itself. Numerous open-source supporters are still enhancing printable components and making designs available. Such community initiatives are quick to innovate and run an experiment that might not be a priority for commercial developers.

Barriers That Still Prevent Full Self-Replication

Despite some promising innovations, some challenges are still important. The development of a fully 3D printed 3D printer is still slowed by the following factors.

Economic and Practical Limitations

Although it could be possible to have fully printable components, the overall work of 3D printing could still be more costly or time-consuming than a conventional manufacturing process. Substances that can imitate metal or electronics would require considerable development to be economical.

Regulatory and Material Safety Considerations

Printed materials that are high temperature or conductors of electricity must undergo rigorous testing for safety. In the absence of standardized guidelines, massive adoption is constrained. Consumer printers also have a problem with certification since printed parts might not be satisfactory.

Energy and Process Complexity

The workflow of a 3D printed 3D printer would be complicated, involving a variety of temperatures, materials, and techniques of fabrication. Such a system would need advanced automation, which was well above most existing home or hobbyist devices.

Case Study: 3D Printed 3D Printer from Unnecessary Inventions:

The YouTube creator, Matt Benedetto, recently posted a video on his channel, Unnecessary Inventions, showcasing his journey to 3D print a 3D printer.

The inspiration struck when he stumbled upon a photo online of an incredibly charming, miniature 3D printer. He decided he had to build one himself. After some internet sleuthing, he discovered the design originated from a Japanese designer named Summer Orange. Because the original documentation was entirely in Japanese, Matt used translation software and reached out to the designer via the Discord community. He successfully contacted the designer, secured Beta Test access, and obtained the necessary CAD design files and assembly instructions.

As we previously discussed regarding technical limitations, the creator's claim of "3D printing the 3D printer" actually meant printing all of the structural components and the enclosure. Matt utilized his own print farm, using his signature Teal and White ABS filament to print the chassis, brackets, and shell. Crucially, he also demonstrated the significant quantity of non-printed components he had to purchase, including electronics, stepper motors, nuts, and metal wire. Due to the parts list being in Japanese, with many links pointing to Japanese domestic suppliers, he faced considerable difficulty in sourcing this core hardware.

Assembly and Technical Highlights

-

Assembly Process: Matt described the assembly as an advanced version of adult LEGO. The printer is built to extremely tight tolerances, requiring significant patience to embed the nuts and piece the framework together.

-

Motion System: A fascinating technical detail is that, due to the printer's tiny scale, it does not use traditional timing belts for its CoreXY motion system. Instead, it utilizes metal wire to drive the axes.

-

Wireless Feature: A major highlight is the machine’s completely wireless nature. It is powered by a power bank, making it fully portable for printing anywhere.

-

Build Volume: The build plate is minuscule, measuring only $70 \times 70 \text{mm}$. The creator compared it to the build volume of a Bambu Lab A1 Mini, noting that the miniature machine's print area is only about one-sixteenth the size.

-

Successful Operation: After assembly, the machine successfully ran. Although the first layer exhibited some minor striations (lines) and the top surface wasn't perfectly smooth, it successfully printed the test model. Matt ultimately decided to dedicate the tiny printer to printing hundreds of his own miniature bust models, staying true to his channel's "Unnecessary Inventions" theme.

Key Takeaway: The Limits of Self-Replication

Despite the creator's declaration of having "3D printed a 3D printer," he still needed to purchase the stepper motors, control board, hotend, and wiring. This vividly illustrates a key point: current consumer-grade technology can achieve structural self-replication (the 'skeleton'), but it cannot yet achieve electromechanical core self-replication—the ability to reproduce the 'brain and muscles.'

Nevertheless, Matt's process of connecting with a Japanese designer via Discord to obtain the design files—a model of global sharing of digital designs and local hardware manufacturing (Distributed Manufacturing)—showcases the cross-lingual collaboration within the 3D printing community. This spirit of DIY ingenuity and Open Source culture is the core appeal of 3D printing.

Conclusion: How Close Are We Really to 3D Printed 3D Printers

Though we are steadily heading towards more advanced and self-copying manufacturing systems, a fully 3d printed 3d printer remains years, maybe decades away.

Structural components, simple mechanics, and other functional housings can already be printed; however, the fundamental parts, including electronics, sensors, motors, and processors, are still reliant on traditional manufacturing.

The latest high-performance machines, such as the

Flashforge AD5M Pro, demonstrate how much the commercial technology has developed, but they also show how complex the parts that cannot be 3D printed may be.

The vision of a complete 3D printed 3D printer is not impossible, although it demands breakthroughs in the area of materials science, printed electronics, multi-material printing, and precision engineering. We are already nearer than ever, but then again, we are at the initial stages of this transformative journey.