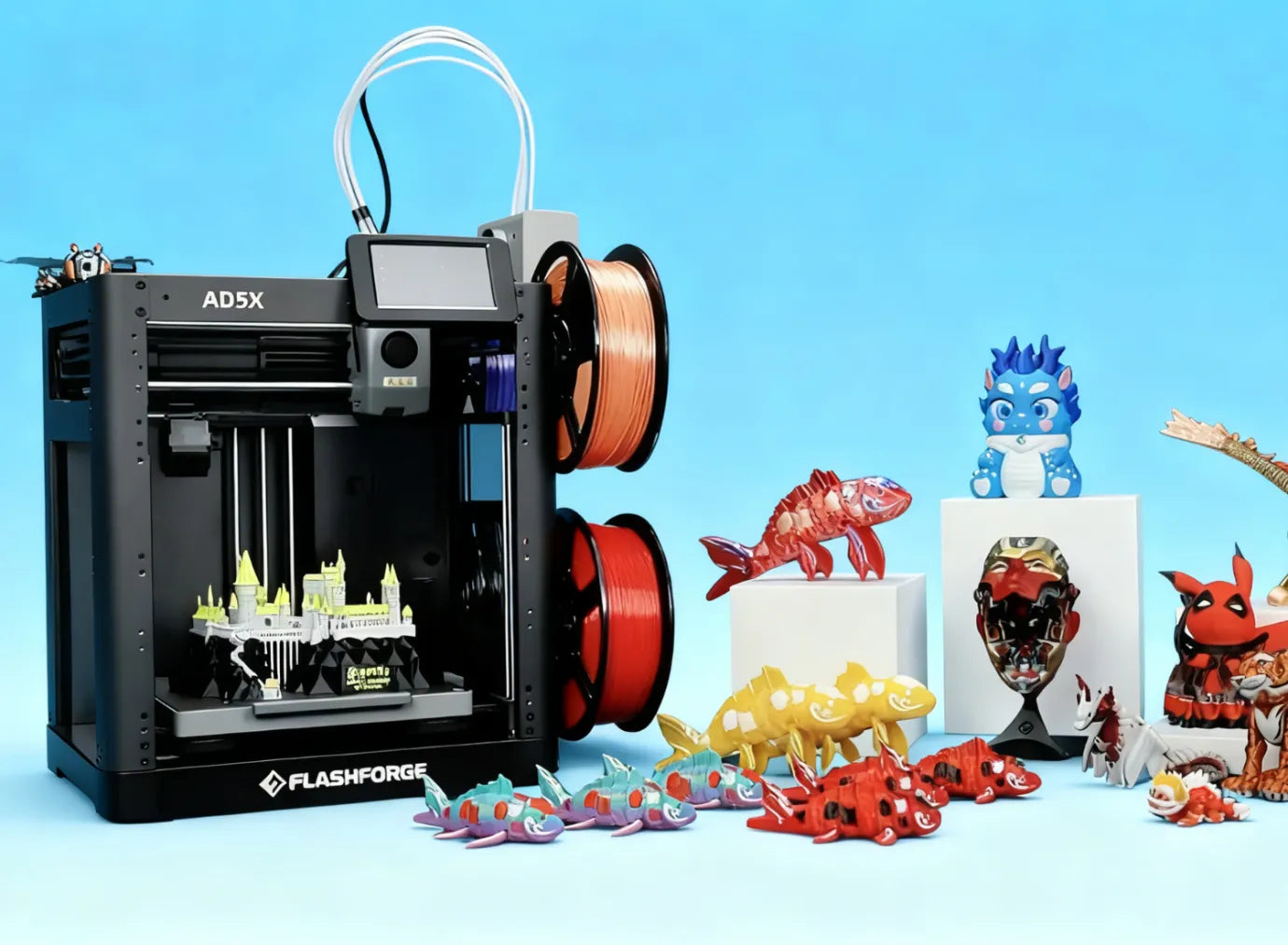

When just venturing into 3D printing, the first and most significant choice you will make is the

filament type selection. The PLA vs ABS filament debate is one of the most widespread among makers, professionals, and hobbyists alike, although there are dozens of materials to choose from as well.

A superficial look at the two materials would lead to the conclusion that they are the same; they are high-temperature thermoplastics that harden during cool-down. They, however, vary radically in the way they are printed, performed and finished. The decision between them is not only in terms of price, but also in terms of knowing what your prints should do.

PLA vs ABS Filament Selection Matters More Than You Think

All print success, part strength, surface finish, and even safety factors like fumes or food contact suitability depend on the kind of filament you use. As an example, when printing at home, PLA could be the best option because of its low smell and its being actually comfortable to work with. However, in the case of designing mechanical components or parts that have to be used externally, ABS may be more suitable.

It is important to consider the behaviour of both materials before plunging into your next print and what they would be better suited to. What is different about each of them?

What is PLA Filament?

PLA (Polylactic Acid) is undoubtedly the most popular filament in the world of 3D printing and justifiably so. It is produced using renewable materials such as corn starch or sugarcane and is, therefore, environmentally friendly and biodegradable.

PLA has been characterized by a smooth surface finish, bright coloration and low printing temperature (usually about 190-220 °C). It is the ideal place to start as a beginner because it does not need a heated bed, and therefore, there is a limited amount of warping.

Why Most Beginners Start with PLA

New users should use PLA since it is extremely simple to print. It adheres easily to print beds, does not produce heavy smells, and fits almost all 3D printers available on the market.

The Flashforge HS-PLA Filament is a great product to have, should you require a high-quality product. It is highly dimensionally accurate, exhibits minimal amounts of shrinkage, and offers bright colour reproduction, which is best suited to printing models, prototypes, and ornamental objects. Also, it comes in various colors, thus you can use your innovative designs and not fear that the print will not come out in the end.

The Pros and Cons Everyone Mentions

Here are some pros and cons:

Pros of PLA:

-

Easy to print, even on entry-level printers

-

Environmentally friendly and biodegradable

-

Smooth surface finish and detailed prints

-

Low odor during printing

-

Excellent dimensional accuracy with minimal warping

-

Compatible with most 3D printers and no heated bed required

-

Wide variety of colors and specialty blends (e.g., silk, wood, metallic)

-

Affordable and easily available

Cons of PLA:

-

Lower heat resistance

-

Brittle compared to ABS

-

Not suitable for outdoor or high-stress applications

-

Prone to moisture absorption, which can affect print quality

-

Softens under direct sunlight or high temperatures

-

Limited post-processing options compared to ABS

-

Can clog nozzles if stored improperly

Although these are the general points, another lesser-known positive feature of PLA is that it retains its strength with time when kept adequately, making it an excellent choice for long-term display models and prototypes.

What is ABS Filament?

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic that is derived from petroleum; it is tough, flexible, and strong. It is employed in daily commodities such as LEGO bricks to car components due to its strength and capacity to endure impact and heat.

ABS 3D print filament, however, needs a little more experience to print successfully. It normally prints at elevated temperatures (230 - 250 °C) and requires a preheated bed to avoid warping.

Why ABS is Used for Functional Parts

ABS is the best when it comes to strength, toughness, and temperature resistance. It can be used in mechanical prototyping, enclosures, and working tools.

The Flashforge ABS Filament is designed in such a way that it minimizes the warping and still has good layer adhesion and impact resistance. It has a high thermal stability that can be relied upon to perform well even under the harsh print conditions.

In case you deal with heavy mechanical components, such a filament provides the professional level of strength required to deliver high performance.

The ABS Filament vs PLA Comparison on Paper

|

Property

|

PLA

|

ABS

|

|

Print Temp

|

190–220°C

|

230–250°C

|

|

Bed Temp

|

Optional

|

Required

|

|

Strength

|

Moderate

|

High

|

|

Flexibility

|

Low

|

Medium

|

|

Heat Resistance

|

Low

|

High

|

|

Odor

|

Mild

|

Strong

|

|

Biodegradable

|

Yes

|

No

|

To sum up, PLA is denser and stiffer, whereas ABS is lighter and more impact-resistant.However, the correct decision lies in your application case.

PLA vs ABS Filament: A Head-to-Head Strength Comparison

Speaking of PLA vs ABS filament, strength is not merely about the level of force that a material can withstand until it breaks, it is more about the mechanics of it under stress.

What "Strength" Really Means

ABS is better in terms of impact resistance, whereas PLA is stronger in tensile. This implies that PLA will be able to maintain shape under tension but may crack when dropped whereas ABS can bend a little further before breaking.

Layer Adhesion vs. Impact Resistance

ABS bonds its layers better, hence, it is more resistant in parts that are subjected to mechanical forces. The rigidity of PLA however makes it more dimensional accurate, which is best used on detailed prototypes or visual models.

The Surprising Durability of PLA in Real-World Applications

The current PLA formulations, including Flashforge HS-PLA Filament, are advertised as brittle, but the durability is very impressive. Many hobbyists have been working with PLA as the parts such as brackets, enclosures and these parts would support surprisingly well in natural indoor conditions.

When you have finished a process of printing, post-processing is a useful step to provide better appearance and performance.

Acetone Smoothing

ABS responds well to the acetone vapor, which also leaves layer lines smooth and provides a shiny surface. PLA, on the other hand, is not soluble in acetone and hence this method is only applicable to ABS.

Sanding and Painting

Both can be sanded and painted, but ABS is generally easier to sand and post-process. PLA is harder and tends to gum up sandpaper due to friction heat. Apply a fine-grit sandpaper after which primer and paint are applied to give the models a professional look.

3D Printer Filament ABS vs PLA: How to Choose the Right One for You

Choosing a filament depends on the level of your skill, the printing environment and the use of prints.

When to Always Choose PLA

Choose PLA if:

-

You’re new to 3D printing

-

You are printing decorative or prototype models.

-

You desire to have a low smell and no trouble handling.

-

You want bright colors and smooth finishes for aesthetic models

-

You’re printing educational projects, miniatures, or cosplay props

-

You’re using an open-frame 3D printer without a heated enclosure

When to Actually Choose ABS

Choose ABS if:

-

You require components that are resistant to heat or mechanical forces.

-

You are printing machinery, boxes or car parts.

-

You have a closed printer to minimize warping.

-

You plan to sand, drill, or chemically smooth your prints for a polished finish

-

You need stronger parts for everyday or industrial use

-

You’re designing items that will be used outdoors or in warm environments

Is PETG a Better Choice Than ABS vs PLA Filament?

PETG sits between PLA and ABS, as

this article states. It is cheaper to print as compared to ABS, yet stronger and more flexible than PLA. Nonetheless, PLA vs ABS filament will continue to be the characteristic choice in most projects, should you be concerned with the quality of visual appearance

versus high durability.

Final Verdict

PLA and ABS have their role in 3D printing. Newcomers should start with PLA, which is easy to work with, cheap, and suited to training. To the professional, ABS is still the choice of functional and high-strength components.

However, PLA vs ABS filament is not the question of which one is best, but of which is best based on your and your project's requirements. You can make a good decision, and your 3D prints will reward you.